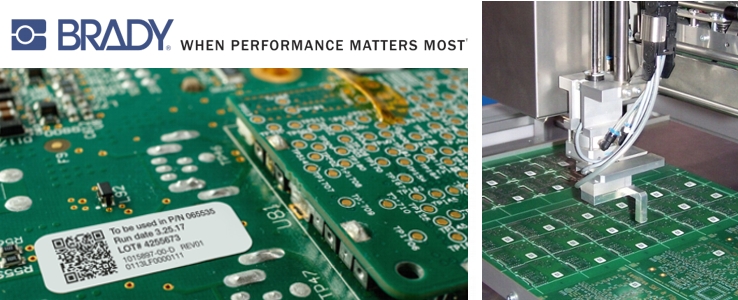

Brady Corporation presents a complete and reliable labelling solution for printed circuit boards that can automate traceability and generate smart manufacturing data about SMD production lines at affordable costs

Track every printed circuit board

Brady offers a complete traceability solution that can connect every circuit board in production to a Smart Factory set up. With Brady's solution, circuit boards can generate data and send these to a Manufacturing Execution System, to other machines and production cycles, or to the supply chain both up and downstream.

Discover every component of Brady's complete traceability solution in the online brochure!

Reliable labels

Brady's reliable printed circuit board labels are designed for auto-apply and can keep 2D codes and barcodes legible in PCB manufacturing conditions so they can be read by scanners throughout a production process.

-Print and apply labels: polyimide labels designed to stay attached and remain legible in temperatures up to 300?C, or when exposed to typical PCB chemicals and cleaning processes.

-Laser engravable: designed to endure PCB production processes and increase the contrast of laser markings to make them easier to read for scanning systems.

-Masking film: designed to protect PCB's during manufacturing processes, including wave soldering and hot air levelling. The masking film can be removed cleanly.

Test Brady's reliable labels in your environment and see how they perform.

Automate

A fully automated printed circuit board labelling solution can enable traceability and manufacturing data analysis without human interference. Brady offers several automation solutions depending on one?s needs:

-BSP61 Print and Apply System: offers consistent in-line printing, accurate positioning and application of labels in almost all manufacturing applications.

-ALF 14 Label Feeder: offers effective automated label feeding, is fast, efficient and easy to use and can be implemented anywhere along the production line.

-BradyPrinter i7100 Industrial Label Printer: offers durable and highly accurate label printing for business-critical high volume identification challenges.

-Scanners: with portable or integrated scanners, traceability systems can evolve beyond supply chain requirements and generate data that can be analysed to create business cases for production optimisation.

Get a hands-on experience with our systems to experience how automated traceability can optimise your business. Request a demo!

Meet Brady at Middle East Electricity 2019 in Dubai (UAE), Brady booth will be in hall 3 - 3F29!

Brady will showcase its wide range of products for wire identification, labelling materials and tools for wire and cable marking in the electrical, electronic and telecommunication markets, high-performance identification products, labels and signs and the printers to create and print them.