In The Spotlight

DEWA to award water pipeline contract in Q4 2025

Dubai Electricity and Water Authority (DEWA) is expected to award the engineering, procurement, and construction (EPC) contract for its Glass Reinforced Epoxy (GRE) Water Transmission Pipelines Works – Project 2 in the fourth quarter of 2025, according to Zawya Projects.

The tender, titled “Supply, Installation, Testing & Commissioning of Glass Reinforced Epoxy Water Transmission Pipelines Works – Project 2,” was issued on 4 June 2025, with bids submitted by 14 August.

Zawya Projects indicated that the contract award is likely to be confirmed in early October, with project completion targeted for the fourth quarter of 2027.

DEWA’s website shows that six firms submitted bids, of which five were accepted.

The accepted bids include Al Nasr Contracting Company at US$116mn, with a discounted amount of US$110mn if both sections are awarded; Dineshchandra R. Agrawal Infracon at US$119.3mn, discounted to US$111mn; Green Oasis General Contracting at $78.9mn; Tristar Engineering & Construction at US$111.5mn; and Oman International Telecommunication Contracting at US$107mn, discounted to US$104mn for both sections.

A bid from Gulf Petrochemical Services was listed at US$40.15mn.

Hills & Fort Construction’s bid of US$170mn was not accepted.

The project forms part of DEWA’s ongoing efforts to enhance water transmission infrastructure in Dubai, with GRE pipelines providing durability, corrosion resistance, and long-term operational efficiency.

ACCIONA unveils Atlas to drive safer, greener construction

ACCIONA, a global leader in sustainable infrastructure, has unveiled a new digital platform designed to transform the way construction projects are managed worldwide. The system, known as Atlas, integrates multiple digital tools into a single platform to enhance efficiency, safety and sustainability across a wide range of infrastructure developments.

The launch reflects ACCIONA’s ongoing commitment to support the ambitious development and sustainability agendas of the Middle East, where governments are increasingly embracing digitalisation and green technologies to deliver large-scale infrastructure projects.

Atlas brings together data monitoring, automation and real-time analytics to optimise project performance. Its user-friendly design allows project teams to monitor, control and manage construction activities seamlessly.

The platform has been designed with versatility in mind. Whether applied to roads, highways, tunnels, railways, metros, ports or buildings, Atlas can be customised to the specific needs of each project. Its modular, scalable structure enables clients to choose from a wide range of applications including tunnel boring machine (TBM) data management, geotechnical monitoring, asset tracking, concrete traceability and earthwork production tracking.

Beyond performance optimisation, Atlas strengthens workplace safety. The platform incorporates air quality monitoring, emergency alerts, video surveillance and worker location tracking in real time, giving project managers the ability to identify hazards quickly and respond effectively.

Sustainability is also at the core of the system. In line with Saudi Arabia’s Vision 2030 and the UAE’s Net Zero 2050 strategy, Atlas integrates environmental monitoring tools to track both real-time and historical data, helping to reduce environmental impacts and support decarbonisation initiatives. Fully digitalised concrete production improves compliance, lowers emissions and enhances traceability across the supply chain. Automated inventory and maintenance management tools further reduce waste and improve operational efficiency.

While Atlas is a new launch for the Middle East, the platform has already been successfully deployed on major international projects. In the United States, it supports the Fargo-Moorhead Flood Diversion project – one of the country’s largest infrastructure undertakings – with fleet and fuel management systems designed to cut carbon emissions.

In Brazil, Atlas is being used on the São Paulo Metro Line 6 to improve TBM operations and instrumentation monitoring. The system has also been applied to a reservoir project in Chile and the S19 road tunnel in Poland, where it has optimised asset tracking and strengthened safety systems.

Supporting Middle East transformation

By bringing its global expertise and proven technologies to the Middle East, ACCIONA aims to accelerate the region’s digital transformation in construction. Atlas provides a powerful solution for governments and developers looking to balance rapid urbanisation with sustainable practices, while also ensuring worker safety and operational excellence.

With its focus on integration, adaptability and environmental responsibility, Atlas marks a step forward in how infrastructure is delivered – smarter, safer and more sustainable.

Saudi Arabia awards US$42mn mining exploration licences

Saudi Arabia has awarded exploration licences for 25 sites in the Nabitah–Ad Duwayhi belt, located in the Makkah region, to nine local and international companies and consortia. The winners have committed more than SAR156mn (US$42mn) in exploration spending, according to the Ministry of Industry and Mineral Resources.

The successful bidders include four consortia: Ma’aden–Hancock Prospecting, Ajlan and Bros Mining–Shandong Gold Group, Technology Experts–Andiamo Exploration, and McEwen–Sumo Holding. In addition, five standalone companies secured licences: Al-Eitilaf Al Mumayaz for Mining Company, Saudi Gold Refinery, Batin Al-Ard for Gold, Aurum Global Group, and Almasar Minerals.

The ministry confirmed that competition for the final site, ND26, was suspended after exploration spending bids exceeded technical evaluations and reached levels deemed commercially unfeasible. The site will be re-evaluated according to the approved timeline under the Mining Investment Law.

Further bidding rounds are planned, with competition for an additional 10 sites in the same belt resuming from 16–18 September. Results will be announced after all regulatory procedures are complete. Another 162 mining sites in the Al-Naqrah and Al-Sukhaybirah Safra belts in the Madinah region will be offered from 28 September. These form part of the ministry’s target to make over 50,000 sq km of mineral-rich belts available by 2025.

Saudi Arabia’s mineral resources are estimated at more than SAR9.4tn, underscoring the sector’s role as a cornerstone of Vision 2030. The Al-Baha region alone is valued at nearly SAR285.4bn (US$76bn) and is rich in resources including gold, silver, copper, zinc, lead, feldspar, marble, and pozzolan. The region also contains mineralised belts for gold, copper, and zinc, as well as 19 mining complexes dedicated to building materials.

The Kingdom views mining as a key driver of economic diversification and aims to position the sector as the “third pillar” of its economy alongside oil and petrochemicals. By accelerating exploration and development of its mineral wealth, Saudi Arabia is seeking to enhance its global competitiveness in mining and attract further international investment.

How can ERP systems reshape construction in the Middle East?

The Middle East continues to lead the world in ambitious infrastructure and construction projects. From Saudi Arabia’s giga-developments to urban transformation initiatives across the Gulf, contractors and owners are under immense pressure to deliver projects that are larger, faster, and more complex than ever before. Against this backdrop, digital transformation has become not only a competitive advantage but a necessity.

Enterprise Resource Planning (ERP) systems have long been used in finance and manufacturing. Yet, in construction—an industry defined by unique project-based challenges—traditional ERP often fails to deliver. The sector requires platforms aligned with the Work Breakdown Structure (WBS) and Bill of Quantities (BoQ), the twin pillars of project planning and cost estimation. Without real-time visibility into time and cost benchmarks, contractors risk delays, budget overruns, and compliance gaps.

This has given rise to construction ERP platforms designed exclusively for project delivery. By integrating engineering, procurement, scheduling, and cost control, these solutions provide contractors with a single digital backbone for managing complex projects. Instead of static reports, project leaders gain dynamic insights into resource allocation, cash flow, and progress against milestones—empowering them to act before risks escalate.

One company driving this transformation is DANAOS Projects Software Solutions LLC, a Dubai-based limited liability company with offices in the United Arab Emirates, Greece, and the Philippines. Its flagship platform, ProjectVIEW ERP, is a tier-one cloud ERP developed specifically for large construction and infrastructure enterprises.

Unlike generic systems, ProjectVIEW ERP continuously benchmarks every activity against WBS-defined timelines and BoQ-based budgets. This creates a “quantum cost control” environment where deviations are identified instantly, and corrective actions can be implemented without disrupting compliance or project governance. Designed as an ERP for construction companies, the platform empowers contractors to manage mega projects with precision and transparency.

At the same time, ProjectVIEW ERP reflects a forward-thinking approach powered by structured data. By standardising operations from site to office and office to site, the system weaves a data fabric that connects teams, processes, and stakeholders across the entire project lifecycle. This ensures that decisions are informed by accurate, up-to-date information, reducing risks of miscommunication and enhancing collaboration.

Artificial Intelligence (AI) is further extending these capabilities. DANAOS Projects has announced plans to embed AI-driven agents within ProjectVIEW ERP to automate repetitive tasks, predict cost overruns, and detect schedule risks before they materialise. This positions the platform not just as an ERP, but as a digital command center capable of orchestrating mega projects in line with the Middle East’s long-term vision for innovation and sustainability.

Beyond traditional building and infrastructure projects, ProjectVIEW ERP also supports offsite construction, modular construction, and prefabrication workflows. These methods are increasingly adopted across the region to accelerate delivery timelines, improve quality, and enhance sustainability. By extending ERP functionality to these industrialised construction models, ProjectVIEW enables enterprises to maintain full visibility and cost control.

As Middle Eastern nations accelerate their national visions, construction companies will increasingly depend on cloud ERP ecosystems to meet sustainability, efficiency, and governance objectives. Project-specific ERP systems are not only supporting tools—they are becoming the central command centers of project delivery.

By weaving structured data across the construction lifecycle, project-specific ERP platforms such as ProjectVIEW ERP are enabling contractors in the Middle East to deliver mega projects on time, within budget, and to the highest international standards.

More details on https://www.danaos-projects.com

UAE ranks among world’s safest skies with top ICAO score

The UAE has achieved a score of 98.86% in the International Civil Aviation Organization’s (ICAO) Universal Safety Oversight Audit Programme, placing it among the world’s top performers in aviation safety, according to a new report from the General Civil Aviation Authority (GCAA).

The GCAA credited this result to strong regulatory oversight, significant investment in human capital, the adoption of advanced technologies, and alignment with global best practices. The findings were shared in a Wam news agency report, underscoring the UAE’s determination to position its aviation sector at the forefront of international safety standards.

As part of its broader efforts to document and share progress, the authority has launched a new series of analytical reports titled A Closer Look: Civil Aviation in the UAE. The most recent edition, Building One of the World’s Safest Skies, highlights milestones in aviation safety and outlines the challenges and opportunities that lie ahead.

At the core of these achievements is the UAE’s National Aviation Safety Plan (2023–2026). Implemented under the State Safety Programme and aligned with ICAO’s Global Safety Plan, it focuses on reducing operational risks, strengthening oversight, and embedding a safety-first culture across the sector. In 2024 alone, the GCAA carried out more than 900 safety oversight activities, including inspections, licensing, infrastructure checks, and airspace reviews.

Technology has been a major enabler of progress. The authority has rolled out an AI-powered, risk-based oversight system that provides real-time risk dashboards, automated audit prioritisation, and operator self-assessment portals. This system enhances efficiency and regulatory reach without increasing staff numbers, reflecting the UAE’s We the UAE 2031 vision of combining innovation with effective governance.

Other notable initiatives include the Voluntary Reporting System (VORSY), which encourages pilots and operators to report potential hazards, and the Communicable Disease Management Protocol (CAR-CDMP), developed in collaboration with the Ministry of Health and Prevention. This protocol—recognised by both ICAO and the World Health Organization—sets new standards for preventing and managing disease transmission within aviation operations.

The UAE has also assumed a leadership role on the global stage by hosting and organising several high-profile aviation gatherings. These have included the ICAO Conference on Aviation & Alternative Fuels (CAAF/3) in 2023, the ICAO RASG-MID meetings in 2024, the ICAO Global Implementation Support Symposium in 2025, and the Global Sustainable Aviation Market (GSAM) 2025, alongside its annual UAE Aviation Safety Conference.

The GCAA emphasised that safety in the UAE is not treated as a procedural requirement, but as the foundation of aviation operations. It underpins passenger trust, ensures the continuity of air travel, and safeguards lives. The authority stressed that these principles drive every initiative undertaken in the sector, reinforcing the UAE’s position as one of the safest and most trusted aviation hubs in the world.

IRENA will share its latest analysis on the shifting geopolitical and economic dynamics. (Image source: IRENA)

IRENA Council convenes in Abu Dhabi

The 29th meeting of the International Renewable Energy Agency (IRENA) Council will convene on 11 September in Abu Dhabi, bringing together more than 400 government officials from 169 countries and the European Union.

Over two days, delegates will provide strategic guidance on IRENA’s work programme while tackling critical issues driving the global energy transition.

A central focus will be energy security, with discussions on diversifying supply chains, advancing next-generation technologies, and boosting regional manufacturing capabilities.

IRENA will share its latest analysis on the shifting geopolitical and economic dynamics of renewable energy supply chains, with particular attention to the solar PV sector.

The agenda also includes accelerating investment in sustainable aviation fuels (SAF), which IRENA highlights as essential to decarbonising long-haul aviation.

The Agency will present new initiatives to support SAF projects and channel financing through its platforms, enabling developers and governments to progress projects from early-stage concepts to bankable ventures.

The meeting will conclude with Members outlining future priorities for IRENA, addressing institutional matters, and preparing for the upcoming 30th session.

“Diverse, resilient and transparent supply chains are essential to achieve the tripling renewable power capacity target by 2030,” said IRENA director-general Francesco La Camera. “While the shift toward renewables is a key enabler for energy security and independence, global supply chains remain concentrated in a few nations. Efforts to diversify them, however, must contend with complex economic realities, making the 29th IRENA Council an important opportunity to advance this discussion collectively.”

In his capacity as 29th IRENA Council Chair, H.E. Mr Francisco Chacón Hernández Ambassador of Costa Rica to the UAE, KSA and Jordan said, "IRENA has been and is a successful, inclusive vehicle of a universe of countries in their quest to find solutions towards a sustainable energy of the future. A future, envisioned to fulfill, in time, human aspirations for shared prosperity to all, the younger generations in particular. As a Costa Rican chair of the 29th Council, topics as energy transition, decarbonisation and renewable energies will be on the forefront of our aims and thoughts. True to our Costa Rican idiosyncrasy, we will never impose. We will seek to listen with respect to all, and team up together to get going, always in good faith."

The residential sector continues to lead the Kingdom’s construction activity. (Image source: dmg events)

Saudi Arabia’s Western region powers US$692bn construction boom

Saudi Arabia’s Western region is driving a construction pipeline worth US$692bn, accounting for 55% of the Kingdom’s US$1.25tn development plan, according to Knight Frank.

The region, led by Jeddah, is seeing projects of unprecedented scale that are reshaping its skyline and positioning it at the centre of Saudi Arabia’s Vision 2030 transformation.

Saudi Arabia’s construction output reached US$141.5bn in 2023, up 4.3% from the previous year, and is forecast to hit US$181.5bn by 2028, making it the largest construction market globally.

In Jeddah, landmark developments include Jeddah Central, a US$19.9bn coastal redevelopment featuring a marina, beaches, museums, a stadium, and 2,700 hotel rooms; Jeddah Tower, set to surpass 1 km in height and become the world’s tallest building; and the restoration of UNESCO-listed Al-Balad.

Additional mega projects such as Jeddah Cove and Airport City further highlight the city’s diverse blend of heritage, commerce, leisure, and infrastructure.

The residential sector continues to lead the Kingdom’s construction activity, accounting for US$43.5bn, or 31% of output in 2023, with projections to reach US$56.9bn by 2028.

Power and utilities follow closely, valued at US$35.1bn in 2023 and expected to rise to US$46.5bn by 2028.

This scale and diversification reflect the breadth of opportunity across the construction ecosystem, opening doors for both local and international companies.

The Western region’s construction boom is also spurring new demand for advanced technologies, expertise, and sustainable practices.

With projects on a scale never seen before in the Kingdom, companies are positioning themselves to align with Vision 2030 objectives, tapping into opportunities ranging from smart urban design and digital construction to offsite solutions and renewable energy integration.

Industry leaders, investors, architects, engineers, and developers are increasingly turning their focus towards Jeddah, where rapid urbanisation and large-scale developments are fuelling demand for cutting-edge products and services.

Amidst all this, Jeddah Construct is to return to the city from 28-30 September.

Jeddah Construct, the largest construction gathering in Saudi Arabia’s Western Province, serves as a vital meeting point for industry professionals, offering three days of networking, business opportunities and knowledge sharing. By drawing influential decision-makers and highlighting top manufacturers and suppliers, the event has become a key destination for those looking to engage with Jeddah’s fast-growing construction sector.

“Jeddah Construct reflects the scale and ambition of the construction market in Saudi Arabia’s Western Province. With significant investment concentrated in the region, the event offers a strategic setting for companies to connect with industry leaders, present their solutions and explore opportunities aligned with the Kingdom’s Vision 2030 objectives,” said Muhammed Kazi, senior vice president – construction at dmg events. “It is an environment where the market’s ambitions for growth and the partnerships shaping its future come together.”

SafeStart Trainer Certification Level 1 Course - Riyadh

Venue:

Riyadh, Saudi Arabia

Dates:

21-22 October 2025

Website:

https://events.offsnet.com/SafeStartTrainerCertificationLevel1Course-Riyadh

21 Oct 25 - 22 Oct 25

Venue:

Riyadh, Saudi Arabia

Dates:

21-22 October 2025

Website:

https://events.offsnet.com/SafeStartTrainerCertificationLevel1Course-Riyadh

Rheem launches HVAC system to cut energy use

Rheem Middle East, a global leader in HVAC and water-heating solutions, has introduced Rheem Centurion, a next-generation system designed to set new performance standards in heating and cooling across the MEA region.

Engineered for maximum efficiency, Rheem Centurion delivers up to 84% energy savings by recycling waste heat from air conditioning units to produce hot water while cooling indoor spaces at the same time. This dual functionality helps reduce energy costs, cut carbon emissions, and ensure reliable year-round performance for residential, commercial, and hospitality applications.

Tailored to the region’s climate and sustainability priorities, Rheem Centurion supports energy-smart building technologies in line with regulatory requirements and long-term green goals. As urbanisation, population growth, and large-scale developments accelerate across the MEA, the system offers developers and operators a future-proof solution that balances comfort with sustainability.

Versatility is central to its design. Rheem Centurion integrates seamlessly into a wide range of building types and can heat water up to 70°C, making it particularly suitable for high-demand facilities such as hotels, hospitals, resorts, and multi-family housing. Its advanced smart controller enables users to optimise efficiency through three operating modes—cooling, heating, or simultaneous use—while maintaining whisper-quiet operation to enhance indoor comfort.

By capturing and reusing otherwise wasted energy, Rheem Centurion not only supports cost savings but also delivers measurable environmental benefits, positioning it as a key innovation for sustainable infrastructure across the MEA region.

Brian Hempenstall, vice president and general manager at Rheem Middle East, said, “Rheem Centurion is more than a product launch; it represents a significant step forward for the built environment in this region. By combining air conditioning and hot water generation in a single, highly efficient system, we are helping developers, hoteliers, and homeowners meet today’s demands while preparing for tomorrow’s sustainability standards. At Rheem, our mission is to deliver comfort without compromise — comfort that is smarter, cleaner, and built for the future of the Middle East and Africa.”

TAQA acquires GS Inim to expand global water platform

Abu Dhabi National Energy Company PJSC (TAQA) has signed an agreement to acquire 100% of GS Inima, a Madrid-headquartered water treatment and desalination specialist, from GS Engineering & Construction.

The deal, valued at about US$1.2bn, will accelerate TAQA’s international water growth strategy and bring GS Inima fully under its ownership.

Operating in ten countries, including Spain, Brazil, Mexico, the US and Oman, GS Inima runs around 50 active projects, including 30 long-term PPPs.

The acquisition will add 171 million imperial gallons per day (MIGD) of desalination capacity to TAQA’s existing 1,250 MIGD portfolio. It will also contribute 264 MIGD of drinking water and 572 MIGD of wastewater and industrial water treatment capacity, alongside a water management business serving 1.3mn people.

In 2024, GS Inima reported revenue of €389mn (US$423mn) and EBITDA of €106mn (US$115mn), underpinned by concession agreements offering stable cash flows.

Jasim Husain Thabet, TAQA’s Group CEO and managing director, said, “This acquisition represents a transformational step in TAQA’s growth and water strategy. GS Inima brings proven operational and technical strength on a global scale, and we are proud to welcome them into the Group. Together, we will accelerate our ambition to become a leading international water player, expanding our reach and capabilities across strategic growth markets in the Middle East, Europe, and the Americas, while delivering innovative, low-carbon water solutions to communities around the world.”

The transaction, subject to regulatory approvals, is expected to close in 2026.

How can ERP systems reshape construction in the Middle East?

The Middle East continues to lead the world in ambitious infrastructure and construction projects. From Saudi Arabia’s giga-developments to urban transformation initiatives across the Gulf, contractors and owners are under immense pressure to deliver projects that are larger, faster, and more complex than ever before. Against this backdrop, digital transformation has become not only a competitive advantage but a necessity.

Enterprise Resource Planning (ERP) systems have long been used in finance and manufacturing. Yet, in construction—an industry defined by unique project-based challenges—traditional ERP often fails to deliver. The sector requires platforms aligned with the Work Breakdown Structure (WBS) and Bill of Quantities (BoQ), the twin pillars of project planning and cost estimation. Without real-time visibility into time and cost benchmarks, contractors risk delays, budget overruns, and compliance gaps.

This has given rise to construction ERP platforms designed exclusively for project delivery. By integrating engineering, procurement, scheduling, and cost control, these solutions provide contractors with a single digital backbone for managing complex projects. Instead of static reports, project leaders gain dynamic insights into resource allocation, cash flow, and progress against milestones—empowering them to act before risks escalate.

One company driving this transformation is DANAOS Projects Software Solutions LLC, a Dubai-based limited liability company with offices in the United Arab Emirates, Greece, and the Philippines. Its flagship platform, ProjectVIEW ERP, is a tier-one cloud ERP developed specifically for large construction and infrastructure enterprises.

Unlike generic systems, ProjectVIEW ERP continuously benchmarks every activity against WBS-defined timelines and BoQ-based budgets. This creates a “quantum cost control” environment where deviations are identified instantly, and corrective actions can be implemented without disrupting compliance or project governance. Designed as an ERP for construction companies, the platform empowers contractors to manage mega projects with precision and transparency.

At the same time, ProjectVIEW ERP reflects a forward-thinking approach powered by structured data. By standardising operations from site to office and office to site, the system weaves a data fabric that connects teams, processes, and stakeholders across the entire project lifecycle. This ensures that decisions are informed by accurate, up-to-date information, reducing risks of miscommunication and enhancing collaboration.

Artificial Intelligence (AI) is further extending these capabilities. DANAOS Projects has announced plans to embed AI-driven agents within ProjectVIEW ERP to automate repetitive tasks, predict cost overruns, and detect schedule risks before they materialise. This positions the platform not just as an ERP, but as a digital command center capable of orchestrating mega projects in line with the Middle East’s long-term vision for innovation and sustainability.

Beyond traditional building and infrastructure projects, ProjectVIEW ERP also supports offsite construction, modular construction, and prefabrication workflows. These methods are increasingly adopted across the region to accelerate delivery timelines, improve quality, and enhance sustainability. By extending ERP functionality to these industrialised construction models, ProjectVIEW enables enterprises to maintain full visibility and cost control.

As Middle Eastern nations accelerate their national visions, construction companies will increasingly depend on cloud ERP ecosystems to meet sustainability, efficiency, and governance objectives. Project-specific ERP systems are not only supporting tools—they are becoming the central command centers of project delivery.

By weaving structured data across the construction lifecycle, project-specific ERP platforms such as ProjectVIEW ERP are enabling contractors in the Middle East to deliver mega projects on time, within budget, and to the highest international standards.

More details on https://www.danaos-projects.com

TOMRA launches advanced optical sorting tech

One year after commissioning the world’s largest lithium ore sorting facility, Pilbara Minerals is reaping substantial rewards from TOMRA Mining’s advanced sensor-based sorting technology at its Pilgangoora Operation in Western Australia.

The technology has helped deliver the strongest quarterly production figures of FY25, significantly lowered operating costs, and improved overall resource utilisation.

The June Quarter FY25 results underline this transformation. Pilbara Minerals reported a 77% increase in production volumes and a 10% reduction in unit operating costs (FOB) compared with the previous quarter.

These impressive gains are attributed to the ramp-up of the P1000 expansion and the seamless integration of TOMRA Mining’s high-precision sorting systems. By unlocking value from ore that was previously uneconomical to process, the operation is improving both profitability and sustainability.

Commissioned in August 2024 as part of the P680 Expansion Project, the state-of-the-art crushing and sorting plant boasts a capacity exceeding 1,000 tonnes per hour, making it the largest lithium ore sorting facility in the world. At the heart of its success is TOMRA Mining’s sensor-based technology, which enables early waste rejection during processing.

This approach not only enhances lithium recovery rates and final product quality but also reduces energy usage and minimises environmental impact.

The facility addresses one of the core challenges in lithium mining—efficiently managing spodumene ore embedded within barren host rock. It operates with 10 high-precision TOMRA sorters, each tailored to specific particle sizes: four TOMRA COM Tertiary XRT units for fine material, three TOMRA COM XRT 2.0 units for mid-sized particles, and three TOMRA PRO Primary Color sorters for coarse material.

This targeted sorting removes waste material at an early stage, which streamlines downstream processing, cuts annual energy consumption by an estimated 8–15 GWh, and ensures a consistently high-quality lithium product.

The project’s delivery was the result of years of collaboration between TOMRA Mining, Pilbara Minerals, and engineering partner DRA Global. Extensive test work at TOMRA’s Sydney Test Center confirmed the technology’s ability to maintain high lithium recovery and effective waste separation across varying ore types. The facility was completed on time and on budget, demonstrating the strength of the partnership and the operational readiness of the technology.

From a strategic perspective, the sorting facility supports Pilbara Minerals’ long-term objectives of cost optimisation and sustainable growth. It expands the Pilgangoora Operation’s production capacity while establishing the foundation for further growth through the P2000 project, for which feasibility studies are already underway.

With the P1000 expansion fully operational and the next phase of growth in motion, the Pilgangoora Operation stands as a benchmark for innovation in the lithium mining sector.

EGA boosts Al Taweelah output with new ball mill expansion

Emirates Global Aluminium (EGA), the UAE’s largest industrial company and the world’s biggest producer of “premium aluminium”, has completed a debottlenecking expansion at its Al Taweelah alumina refinery, boosting production capacity by up to 50,000 tonnes of alumina per year.

The project centred on the installation of a third ball mill, strengthening operational resilience and paving the way for future output growth at the UAE’s only alumina refinery. Ball mills grind bauxite ore into fine particles for chemical processing into alumina. The additional unit enhances throughput, reduces the risk of unplanned outages, and improves overall availability alongside the two existing mills.

Executed entirely by EGA’s in-house teams, from engineering and project management to construction and commissioning, the project was completed in under two and a half years, recording over 650,000 work hours without a single Lost Time Injury.

Since its commissioning in 2019, Al Taweelah alumina refinery has consistently operated above its nameplate capacity of 2mn tonnes per year. In 2024, the facility supplied 49% of EGA’s total alumina needs, underscoring its strategic role in the company’s integrated value chain.

Abdulnasser Bin Kalban, Chief Executive Officer of Emirates Global Aluminium, said, “This expansion is a key step forward for Al Taweelah alumina refinery, unlocking additional production capacity as we reorient our bauxite supply chain beyond Guinea. It further strengthens our operational resilience and unlocks capacity growth. I thank every member of the team who contributed to this success.”

SolitAir launches Kuwait cargo service from Dubai

UAE-based SolitAir, the country’s dedicated cargo airline, has announced the launch of a scheduled service connecting Dubai World Central (DWC) with Kuwait International Airport (KWI).

The move marks a strategic step in strengthening the carrier’s presence in the Gulf and enhancing its role as a logistics partner for freight forwarders, integrator airlines, and e-commerce platforms across the Middle East and wider Global South.

The new service will cater to Kuwait’s growing demand for fast, reliable cargo transport. SolitAir already carries a diverse range of shipments into and out of the country, including perishables, electronics, courier packages, dangerous goods, and general freight.

The expansion underlines the airline’s ability to handle complex and sensitive cargo with efficiency while maintaining high safety and service standards.

To support the Kuwait operations, SolitAir has appointed Al Hayat International for Air Shipping as its General Sales Agent (GSA). With its local market knowledge and proven air freight expertise, Al Hayat will strengthen the airline’s customer reach and service delivery in the country.

MENA growth

The route is the latest addition to SolitAir’s expanding network, which now covers 26 destinations across the Global South, from the GCC to Africa, Asia and Central Asia.

The airline, which recently secured its Air Operator Certificate (AOC) from the UAE’s General Civil Aviation Authority, currently operates five Boeing 737-800 BCF freighters. It has ambitious growth plans, aiming to increase its fleet to as many as 20 aircraft by 2027.

Operating from its 220,000 sq ft logistics hub at DWC, SolitAir is investing heavily in regional connectivity. Its freighters are equipped to carry a wide variety of specialised shipments, including temperature-sensitive pharmaceuticals, hazardous materials and e-commerce goods, ensuring secure, reliable, and timely deliveries.

The Kuwait service represents another milestone in the airline’s mission to link high-yield trade lanes across the Global South, consolidating its position as a trusted partner in the region’s fast-growing logistics sector.

Talal Al Jeri, CEO of Al Jeri Holdings and Owner of Al Hayat International for Air Shipping, the GSA for SolitAir in Kuwait, said, “We are delighted to partner with SolitAir. Their commitment to speed, reliability and specialised cargo solutions aligns perfectly with the needs of the Kuwaiti market. This partnership will create new opportunities for Kuwaiti businesses to transport goods quickly and efficiently.”

Hamdi Osman, founder & CEO of SolitAir, said, “The launch of our scheduled service to Kuwait comes at a pivotal time, as the ambitious Air Cargo City project at Kuwait International Airport receives the green light to move forward. This initiative is poised to establish Kuwait as a leading logistics hub in the Middle East and North Africa. With cutting-edge facilities and a strategic focus on sustainable growth, this project aligns perfectly with SolitAir’s mission to provide reliable and efficient cargo solutions. With our expanded fleet and the appointment of a strong GSA partner in Al Hayat International, we are committed to supporting Kuwaiti businesses in seizing new opportunities and driving regional trade forward.”

Also read: Air taxis to take-off in Saudi skies?

IEA’s new analysis suggests low-emissions hydrogen production could reach 37mn tonnes a year by 2030

Despite a recent wave of project delays and cancellations, low-emissions hydrogen production is still expected to expand to 2030, though at a slower pace than once signalled, according to the International Energy Agency (IEA).

The 2025 edition of the IEA’s Global Hydrogen Review, tracks developments across the sector with particular focus on low-emissions hydrogen technologies.

Worldwide hydrogen demand reached nearly 100mn tonnes in 2024, up 2% from 2023 and broadly in line with overall energy demand growth. Most of this demand was met by hydrogen produced from fossil fuels without emissions-capturing measures, with oil refining and industry remaining the main consumers.

Producing hydrogen from fossil fuels remains much cheaper globally, a gap widened by falling natural gas prices and rising electrolyser costs. But the report expects the cost gap to narrow by 2030 due to lower technology costs, stronger renewables growth in some regions, and new regulations.

Even so, uptake of low-emissions hydrogen is lagging behind expectations. High costs, regulatory uncertainty and slow infrastructure development have restrained growth, with production projects particularly exposed. The IEA’s new analysis suggests low-emissions hydrogen production could reach 37mn tonnes a year by 2030, down from the 49mn tonnes projected from announced projects just a year earlier.

Not all projects reach completion, meaning actual capacity is likely to be lower. Still, projects already operational, under construction or with a final investment decision are set to increase more than fivefold by 2030, reaching over 4mn tonnes per year. An additional 6mn tonnes could also materialise by the end of the decade if stronger policy support ensures demand.

“Investor interest in hydrogen jumped at the start of this decade thanks to its potential to help countries deliver on their energy goals,” said IEA Executive Director Fatih Birol. “The latest data indicates that the growth of new hydrogen technologies is under pressure due to economic headwinds and policy uncertainty, but we still see strong signs that their development is moving ahead globally. To help growth continue, policy makers should maintain support schemes, use the tools they have to foster demand, and expedite the development of necessary infrastructure.”

China remains the leading force in electrolyser deployment, accounting for 65% of installed or approved capacity and nearly 60% of global manufacturing. But the report warns that Chinese producers face challenges from excess capacity, as more than 20GW per year of output far outstrips current demand.

The review also highlights the shipping sector, finding that adoption of hydrogen-based fuels will require more compatible technologies and port readiness. Nearly 80 ports worldwide already handle chemical products, offering opportunities to manage hydrogen fuels in future.

A special section on Southeast Asia notes that announced projects could boost the region’s low-emissions hydrogen production to 430,000 tonnes a year by 2030, up from just 3,000 tonnes today. Achieving this will require faster renewables deployment, targeted policies and expansion of pilot projects.

Dubai Electricity and Water Authority (DEWA) is expected to award the engineering, procurement, and construction (EPC) contract for its Glass Reinforced Epoxy (GRE) Water Transmission Pipelines Works – Project 2 in the fourth quarter of 2025, according to Zawya Projects.

The tender, titled “Supply, Installation, Testing & Commissioning of Glass Reinforced Epoxy Water Transmission Pipelines Works – Project 2,” was issued on 4 June 2025, with bids submitted by 14 August.

Zawya Projects indicated that the contract award is likely to be confirmed in early October, with project completion targeted for the fourth quarter of 2027.

DEWA’s website shows that six firms submitted bids, of which five were accepted.

The accepted bids include Al Nasr Contracting Company at US$116mn, with a discounted amount of US$110mn if both sections are awarded; Dineshchandra R. Agrawal Infracon at US$119.3mn, discounted to US$111mn; Green Oasis General Contracting at $78.9mn; Tristar Engineering & Construction at US$111.5mn; and Oman International Telecommunication Contracting at US$107mn, discounted to US$104mn for both sections.

A bid from Gulf Petrochemical Services was listed at US$40.15mn.

Hills & Fort Construction’s bid of US$170mn was not accepted.

The project forms part of DEWA’s ongoing efforts to enhance water transmission infrastructure in Dubai, with GRE pipelines providing durability, corrosion resistance, and long-term operational efficiency.

ACCIONA, a global leader in sustainable infrastructure, has unveiled a new digital platform designed to transform the way construction projects are managed worldwide. The system, known as Atlas, integrates multiple digital tools into a single platform to enhance efficiency, safety and sustainability across a wide range of infrastructure developments.

The launch reflects ACCIONA’s ongoing commitment to support the ambitious development and sustainability agendas of the Middle East, where governments are increasingly embracing digitalisation and green technologies to deliver large-scale infrastructure projects.

Atlas brings together data monitoring, automation and real-time analytics to optimise project performance. Its user-friendly design allows project teams to monitor, control and manage construction activities seamlessly.

The platform has been designed with versatility in mind. Whether applied to roads, highways, tunnels, railways, metros, ports or buildings, Atlas can be customised to the specific needs of each project. Its modular, scalable structure enables clients to choose from a wide range of applications including tunnel boring machine (TBM) data management, geotechnical monitoring, asset tracking, concrete traceability and earthwork production tracking.

Beyond performance optimisation, Atlas strengthens workplace safety. The platform incorporates air quality monitoring, emergency alerts, video surveillance and worker location tracking in real time, giving project managers the ability to identify hazards quickly and respond effectively.

Sustainability is also at the core of the system. In line with Saudi Arabia’s Vision 2030 and the UAE’s Net Zero 2050 strategy, Atlas integrates environmental monitoring tools to track both real-time and historical data, helping to reduce environmental impacts and support decarbonisation initiatives. Fully digitalised concrete production improves compliance, lowers emissions and enhances traceability across the supply chain. Automated inventory and maintenance management tools further reduce waste and improve operational efficiency.

While Atlas is a new launch for the Middle East, the platform has already been successfully deployed on major international projects. In the United States, it supports the Fargo-Moorhead Flood Diversion project – one of the country’s largest infrastructure undertakings – with fleet and fuel management systems designed to cut carbon emissions.

In Brazil, Atlas is being used on the São Paulo Metro Line 6 to improve TBM operations and instrumentation monitoring. The system has also been applied to a reservoir project in Chile and the S19 road tunnel in Poland, where it has optimised asset tracking and strengthened safety systems.

Supporting Middle East transformation

By bringing its global expertise and proven technologies to the Middle East, ACCIONA aims to accelerate the region’s digital transformation in construction. Atlas provides a powerful solution for governments and developers looking to balance rapid urbanisation with sustainable practices, while also ensuring worker safety and operational excellence.

With its focus on integration, adaptability and environmental responsibility, Atlas marks a step forward in how infrastructure is delivered – smarter, safer and more sustainable.

Saudi Arabia has awarded exploration licences for 25 sites in the Nabitah–Ad Duwayhi belt, located in the Makkah region, to nine local and international companies and consortia. The winners have committed more than SAR156mn (US$42mn) in exploration spending, according to the Ministry of Industry and Mineral Resources.

The successful bidders include four consortia: Ma’aden–Hancock Prospecting, Ajlan and Bros Mining–Shandong Gold Group, Technology Experts–Andiamo Exploration, and McEwen–Sumo Holding. In addition, five standalone companies secured licences: Al-Eitilaf Al Mumayaz for Mining Company, Saudi Gold Refinery, Batin Al-Ard for Gold, Aurum Global Group, and Almasar Minerals.

The ministry confirmed that competition for the final site, ND26, was suspended after exploration spending bids exceeded technical evaluations and reached levels deemed commercially unfeasible. The site will be re-evaluated according to the approved timeline under the Mining Investment Law.

Further bidding rounds are planned, with competition for an additional 10 sites in the same belt resuming from 16–18 September. Results will be announced after all regulatory procedures are complete. Another 162 mining sites in the Al-Naqrah and Al-Sukhaybirah Safra belts in the Madinah region will be offered from 28 September. These form part of the ministry’s target to make over 50,000 sq km of mineral-rich belts available by 2025.

Saudi Arabia’s mineral resources are estimated at more than SAR9.4tn, underscoring the sector’s role as a cornerstone of Vision 2030. The Al-Baha region alone is valued at nearly SAR285.4bn (US$76bn) and is rich in resources including gold, silver, copper, zinc, lead, feldspar, marble, and pozzolan. The region also contains mineralised belts for gold, copper, and zinc, as well as 19 mining complexes dedicated to building materials.

The Kingdom views mining as a key driver of economic diversification and aims to position the sector as the “third pillar” of its economy alongside oil and petrochemicals. By accelerating exploration and development of its mineral wealth, Saudi Arabia is seeking to enhance its global competitiveness in mining and attract further international investment.

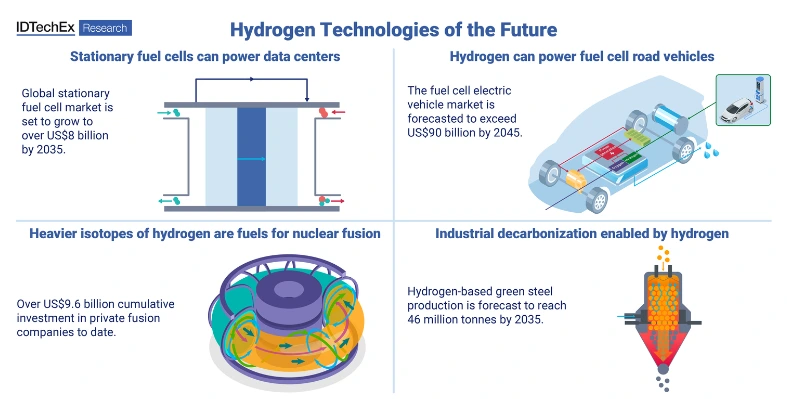

Hydrogen and helium may be made up of small molecules but have a big role to play in the technology innovations of the future

From the natural gas that underpins power generation to the carbon dioxide emissions driving the climate crisis, there is no denying gases have a significant impact on modern life, according to Eve Pope, senior technology analyst at IDTechEx.

The two lightest gases - hydrogen and helium - may be made up of small molecules but have a big role to play in the technology innovations of the future. Key application areas include mobility, power generation, and semiconductor manufacturing.

Hydrogen power

Hydrogen is an energy carrier that could replace fossil fuels to power the future. Fuel cells can convert hydrogen gas into electricity through a chemical reaction with oxygen. Because solid oxide fuel cells have a long operating lifetime and fuel flexibility, they are well-suited to the continuous power generation required for sustainable data centres. As the AI boom continues, some data centres are already using solid oxide fuel cells running on natural gas, with plans to transition over to low-carbon hydrogen once economics and infrastructure can make this commercially feasible.

For cars, fuel cell electric vehicles can also be powered by the reactions between stored hydrogen and oxygen in the air. Markets for fuel cell electric vehicles will depend upon national investments in green hydrogen projects and rollouts of hydrogen refueling stations.

Industrial decarbonisation of iron and steel enabled by hydrogen

For iron and steel, natural gas direct reduced iron (DRI) production using shaft furnaces is already mature. Hydrogen-based DRI (H2-DRI) processes represent the next logical evolution toward greener steel production. Midrex and Energiron shaft furnace plants have successfully demonstrated the use of hydrogen or hydrogen-rich gases, as evidenced in projects like HYBRIT by SSAB in Sweden and HBIS Group in China.

The success of hydrogen-based green steel production will depend heavily upon the availability of green and blue hydrogen and supporting infrastructure, with IDTechEx’s “Green Steel 2025-2035: Technologies, Players, Markets, Forecasts” report forecasting that 46 million tonnes of steel will be produced enabled by hydrogen in 2035.

Hydrogen isotopes for nuclear fusion

Even the heavier isotopes of hydrogen have a role to play. Deuterium and tritium are essential fuels for nuclear fusion technologies, hoped to provide energy-dense, continuous sources of green energy with no risk of meltdown. According to IDTechEx’s “Fusion Energy Market 2025-2045: Technologies, Players, Timelines” report, commercial fusion companies have raised over US$9bn to date, while an increasing number of governments see fusion as the modern day 'space race'. Players are pursuing different reactor designs and fuels, leading to various materials opportunities and supply chain challenges.

Helium required for semiconductor manufacturing

Helium is widely used in manufacturing processes due to its cooling and inert properties. It is crucial for thermal management during semiconductor production. As semiconductor manufacturing advances towards smaller nodes (essential for AI, autonomous vehicles, etc.), reliance on helium will continue to grow. Helium is a finite resource, so technologies for helium production and helium substitutes covered in IDTechEx’s “Helium for Semiconductors and Beyond 2025-2035: Market, Trends, and Forecasts” report will become increasingly essential.

Materials key to hydrogen and helium production

From the ion exchange membranes in electrolyzers for green hydrogen generation to the gas separation membranes used in helium and hydrogen production, the applications explored in this article represent significant opportunities for chemicals and materials companies. Materials for green hydrogen are needed for components such as catalysts, electrodes, porous transport layers, gas diffusion layers, bipolar plates, and gaskets. Innovations include new catalysts with less iridium content to cut costs. For gas separation membranes, the development of new palladium-alloy metallic membranes could unlock ultra-pure H2 separation.

The UAE has achieved a score of 98.86% in the International Civil Aviation Organization’s (ICAO) Universal Safety Oversight Audit Programme, placing it among the world’s top performers in aviation safety, according to a new report from the General Civil Aviation Authority (GCAA).

The GCAA credited this result to strong regulatory oversight, significant investment in human capital, the adoption of advanced technologies, and alignment with global best practices. The findings were shared in a Wam news agency report, underscoring the UAE’s determination to position its aviation sector at the forefront of international safety standards.

As part of its broader efforts to document and share progress, the authority has launched a new series of analytical reports titled A Closer Look: Civil Aviation in the UAE. The most recent edition, Building One of the World’s Safest Skies, highlights milestones in aviation safety and outlines the challenges and opportunities that lie ahead.

At the core of these achievements is the UAE’s National Aviation Safety Plan (2023–2026). Implemented under the State Safety Programme and aligned with ICAO’s Global Safety Plan, it focuses on reducing operational risks, strengthening oversight, and embedding a safety-first culture across the sector. In 2024 alone, the GCAA carried out more than 900 safety oversight activities, including inspections, licensing, infrastructure checks, and airspace reviews.

Technology has been a major enabler of progress. The authority has rolled out an AI-powered, risk-based oversight system that provides real-time risk dashboards, automated audit prioritisation, and operator self-assessment portals. This system enhances efficiency and regulatory reach without increasing staff numbers, reflecting the UAE’s We the UAE 2031 vision of combining innovation with effective governance.

Other notable initiatives include the Voluntary Reporting System (VORSY), which encourages pilots and operators to report potential hazards, and the Communicable Disease Management Protocol (CAR-CDMP), developed in collaboration with the Ministry of Health and Prevention. This protocol—recognised by both ICAO and the World Health Organization—sets new standards for preventing and managing disease transmission within aviation operations.

The UAE has also assumed a leadership role on the global stage by hosting and organising several high-profile aviation gatherings. These have included the ICAO Conference on Aviation & Alternative Fuels (CAAF/3) in 2023, the ICAO RASG-MID meetings in 2024, the ICAO Global Implementation Support Symposium in 2025, and the Global Sustainable Aviation Market (GSAM) 2025, alongside its annual UAE Aviation Safety Conference.

The GCAA emphasised that safety in the UAE is not treated as a procedural requirement, but as the foundation of aviation operations. It underpins passenger trust, ensures the continuity of air travel, and safeguards lives. The authority stressed that these principles drive every initiative undertaken in the sector, reinforcing the UAE’s position as one of the safest and most trusted aviation hubs in the world.

Most Read

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

Latest News

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

-

- COM_CONTENT_ARTICLE_INFO

Most Read

Latest News

More Articles

Challenges in adopting new energy systems

Turing electro-hydraulic control system by Halliburton

Inspection professionals can quickly detect faults and issues to prevent downtime and extend equipment life. (Image source: Flir)

Flir's new thermal imaging camera enhances accuracy

Borouge and Yokogawa trial AI-powered operations

From 10–12 November, the DRIFTx exhibition will showcase smart solutions across land, sea, air, and robotics.

Abu Dhabi to host inaugural Autonomous Week

Oman's Tenable targets Middle East growth

Teledyne GFD's new range of methane detectors

Emerson releases new HMI and SCADA platform update

Over the past few years, EMSTEEL has rolled out more than 30 AI-powered solutions. (Image source: EMSTEEL)

EMSTEEL pushes industrial boundaries with AI and 5G innovation

Rolls-Royce and INERATEC to integrate climate-neutral e-fuels into backup power systems for data centre sustainability