The construction industry is moving away from traditional diesel engines toward greener power solutions.

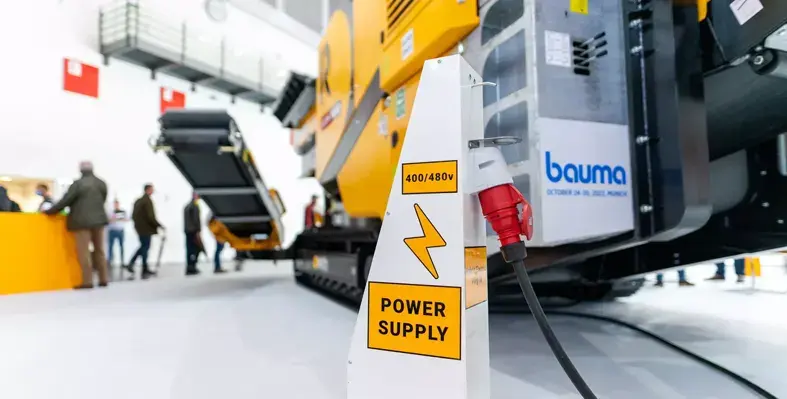

The upcoming edition of bauma, scheduled for 7-13 April 2025, will once again place a spotlight on alternative drive technologies.

Many major players in construction machinery are already committed to decarbonisation. For instance, the Volvo Group has announced that by 2040, it will only deliver fossil-free vehicles. Strabag SE, one of Europe’s largest construction firms, also plans to achieve full climate neutrality by 2040, encompassing the operation of all its construction machinery.

Electric motors are now firmly established as a sustainable drive option for construction equipment. At previous bauma events, exhibitors showcased electric-powered excavators, wheel loaders, rollers, dumpers, and vibratory plates as part of their expanding eco-friendly portfolios. This trend is poised for significant growth: research firm IDTechEx projects that the global market for electric construction machinery could reach US$105bn by 2042.

“Battery electric systems are still primarily suitable for compact machines. Their daily energy and power requirements can be covered by an electric motor and a moderately sized lithium-ion battery in conjunction with a well-defined charging strategy,” says Timo Feuerbach, technical expert for construction machinery and building material machines at the German Mechanical Engineering Industry Asso-ciation (VDMA).

The Bobcat RogueX2 concept loader belongs in this category as a current and pioneering example. The all-electric machine not only operates with zero local emissions, but is also fully autonomous, according to the manufactur-er’s specifications. This year, it received the prestigious Red Dot Design Award in the “Design Concept” category.

HVO as an alternative fuel

It is clear that openness to technology is required for drives that are as climate-neutral as possible across the entire spectrum of the construction industry. For example, a life cycle analysis commissioned by the Liebherr Group came to the conclusion that operating mobile cranes with hydrogenated vegetable oil (HVO) promises the greatest potential for reducing greenhouse gases. Other fuel alterna-tives that can contribute to decarbonizing construction sites are biodiesel, biogas and e-fuels.

Companies and research institutes are also focusing on developing and testing hydrogen powered construction machinery. The Liebherr Components product segment presented prototypes of two hydrogen combustion engines at bauma 2022, and series production was announced for 2025. The industry is also explor-ing potential applications for fuel cells. For example, General Motors and the con-struction machinery manufacturer Komatsu are working together on a hydrogen fuel cell module for an electric dump truck. Komatsu has also developed a medi-um-sized hydraulic excavator with a hydrogen fuel cell system as a concept machine.