In The Spotlight

SIBS and LINQ Modular form Middle East construction alliance

SIBS AB has signed a strategic collaboration agreement with LINQ Modular, part of ALEC Holdings, to accelerate the delivery of large-scale modular developments across the Middle East, marking a significant step in the region’s industrialised construction landscape.

The partnership brings together SIBS’ international manufacturing expertise in volumetric modular construction with LINQ’s regional delivery capabilities and ALEC Holdings’ established on-site construction experience. The companies aim to deliver faster, more predictable and more sustainable residential, commercial and mixed-use developments as demand for high-quality housing continues to rise across the Gulf.

Building on LINQ’s early work in prefabricated and modular construction since its launch in 2020, the collaboration seeks to scale modular delivery across multiple sectors, including residential, hospitality and commercial developments. Subject to project awards and client approvals, the partners have set a shared ambition to deliver at least 1,500 modular units per year through an industrialised and repeatable production and delivery model.

Under the agreement, LINQ will continue to lead market engagement, regulatory approvals and in-country project delivery, supported by ALEC Holdings’ construction execution capabilities. SIBS will provide large-scale industrial production capacity, design-for-manufacture expertise and factory-controlled quality processes, drawing on its global experience in delivering modular housing at scale.

The collaboration is positioned to address one of the region’s most pressing challenges: the need to accelerate residential delivery without compromising on quality, safety or sustainability. Modular construction offers a solution by shifting a significant portion of construction activity into controlled factory environments, reducing on-site timelines and improving consistency.

A key factor underpinning the partnership is the modular construction licence granted by Dubai Municipality to LINQ, enabling the delivery of G+6 residential and commercial buildings in the emirate. Combined with SIBS’ experience in delivering large apartment complexes internationally, the partners are well placed to respond to strong residential demand across major urban centres in the UAE and wider Gulf.

SIBS brings an established international track record, having delivered approximately 7,000 apartments globally. Its modular systems have typically reduced project timelines by around 40%, lowered production costs by up to 30%, and cut energy consumption by up to 50% compared with traditional construction methods.

Erik Thomaeus, CEO of SIBS, said the collaboration represents a major step forward for modular construction in the UAE, combining SIBS’ industrialised production capacity with LINQ and ALEC Holdings’ regional delivery expertise to offer scalable and predictable modular solutions.

Graham Petty, Operations Manager at LINQ, said the partnership builds on years of groundwork to demonstrate the viability of modular construction at the premium end of the market, enabling the delivery of full-spectrum industrialised construction solutions that support speed, certainty and long-term value.

The collaboration is already progressing multiple near-term project opportunities, reflecting growing market momentum and a robust pipeline of modular-led developments across a range of building types.

Cleanova wins filtration contract for UK CO2 project

Cleanova, a global provider of advanced industrial filtration solutions, has secured a contract to supply critical filtration systems for the Liverpool Bay Carbon Dioxide (CO2) Transportation and Storage project, part of the UK government’s HyNet North West low-carbon and hydrogen initiative.

The contract was awarded by Saipem, the international engineering, procurement and construction company responsible for converting an existing gas compression and treatment facility at Point of Ayr, North Wales, into a CO₂ Electrical Compression Station. The facility will enable the permanent storage of captured CO₂ emissions from heavy industry across North West England and North Wales, with compressed CO2 injected into depleted hydrocarbon fields beneath Liverpool Bay.

Under the agreement, Cleanova will supply purpose-engineered filtration units designed to ensure operational efficiency, safety and long-term reliability across the CO2 transportation and storage process. Each unit, weighing around 50 tonnes, will remove residual amines, water, hydrocarbons and other condensed liquids or particulates from the captured CO2 stream. Removing these impurities is critical to protecting compression equipment, maintaining process integrity and enabling safe, long-term storage.

The Liverpool Bay project is a cornerstone of the HyNet North West industrial decarbonisation cluster and is expected to support the capture and permanent storage of up to 4.5 million tonnes of CO2 per year. Once fully operational, the project will make a significant contribution to the UK’s net-zero targets and wider energy-transition objectives.

Macer Braidwood, Cleanova’s global market manager ‐ energy transition, said, “Our custom filtration systems already play a vital role in the energy transition by capturing emissions and purifying process streams across a wide-range of clean-energy applications. Being selected to support the UK's first large-scale carbon capture and storage project is an important milestone for Cleanova. We are proud to partner with Saipem on the Liverpool Bay CCS project and to contribute our filtration expertise to an initiative that will deliver meaningful, long-term environmental impact. It is another step to our mission to provide filtration solutions today for a better tomorrow.”

Op-ed: Manufacturing takes centre stage in the UAE

Once overshadowed by hydrocarbons, the UAE’s manufacturing sector has now become a driving force for innovation, investment, and sustainable growth across the country. Without a doubt, manufacturing is poised to take centre stage in the country’s long-term aspirations for economic growth and resilience.

Various initiatives from the UAE’s visionary leaders all point towards continuously building, enhancing and reinforcing conditions that will further encourage investments and enable industrialisation to thrive and prosper.

Among them is Operation 300bn, the UAE’s national industrial strategy launched in 2021 which aims to more than double the industrial sector’s GDP contribution from AED133 billion in 2021 to AED 300 billion by 2031.

In addition, programmes, projects and initiatives by the Ministry of Industry and Advanced Technology (MoIAT) such as the National In-Country Value Program (ICV), ‘Make it in the Emirates’, the Technology Transformation Program (TTP), and the Industrial Technology Transformation Index (ITTI) have all been designed and geared towards pro-actively pushing forward the UAE’s manufacturing and industrial ambitions.

Clearly, the UAE is well on track on achieving its industrialisation objectives and its relentless pursuit of economic diversification have already produced remarkable results.

In the first quarter of 2025, non-oil GDP grew 5.3% , reaching AED 352 billion, according to the UAE's Ministry of Economy and Tourism (MOET). The ministry also identified manufacturing as the fastest growing economic activity, registering 7.7% growth in Q1 2025.

According to the latest report by Abu Dhabi Customs, Abu Dhabi's non-oil foreign trade grew by 34.7% in H1 2025, reflecting a thriving manufacturing industry and a key source of UAE exports.

Driven by visionary leadership

It is quite evident that the vision of the UAE’s leadership for the future of this great nation is fuelled by a determination to thrive, succeed and lead.

Not only are they aiming and enabling the manufacturing sector to grow, but they also implement a deliberate governmental policy and strategy that focuses on strengthening the adoption of advanced manufacturing, sustainability, and Industry 4.0 technologies including artificial intelligence, the Internet of Things (IoT), and 3D printing.

Over the years, the UAE's manufacturing sector has continuously demonstrated its resilience. In 2022, manufacturing GDP growth surpassed pre-pandemic levels by tallying 8.75% growth.

With Abu Dhabi leading the way with a growth of 9.7% , the emirate even further sharpened its focus on manufacturing with the launch of the Abu Dhabi Industrial Strategy (ADIS) in the same year. As a result, in the first half of 2025, Abu Dhabi's non-oil GDP grew 6.37% year-on-year, according to the Statistics Centre - Abu Dhabi

The attractiveness and pull for foreign investment into the UAE’s manufacturing sector have also remained strong. At the fourth edition of 'Make it in the Emirates', a 122,000-strong participation of delegates from across the world was a clear indication of the global attention to the sector’s growing appeal.

With US$11bn committed to advanced manufacturing over five years, the UAE is sending a clear message: it is open for industrial business, and it is serious about reducing its reliance on oil.

Innovation and sustainability at the core

Recognising the need to catch up with countries with larger and more advanced manufacturing sectors in a globalised market, the UAE is not just building factories – it's building smart factories.

Industry 4.0 technologies are being integrated into production lines, making UAE manufacturing globally competitive. Sustainability is also a priority, with circular economy models becoming standard practice.

Solar-powered facilities take advantage of the abundant sunshine, while water recycling systems ensure efficient use of water in a desert climate.

These are supported by the MoIAT's ITTI, which measures the digital maturity and sustainability practices of factories, provides a roadmap for their digital transformation and encourages the adoption of Industry 4.0 solutions and sustainability best practices.

Turning challenges into opportunities

While there are indeed challenges in the UAE’s journey towards economic diversification and industrialisation, the country’s leaders have cleverly manoeuvred around them and have instead focused on capitalising on the opportunities presented by these challenges. An uneven manufacturing growth among the emirates is being addressed by the federal government through Operation 300bn, with a focus on equitable development.

Among its goals is to create 13,500 new industrial facilities and 25,000 specialised jobs, many of which are being directed toward less industrialised regions.

For instance, MoIAT is working to ensure that Northern Emirates like Ras Al Khaimah, Fujairah and Umm Al Quwain benefit from industrial expansion through tailored support and infrastructure upgrades.

Additionally, the ICV program provides incentives for companies sourcing locally, further benefiting the economy. These initiatives create numerous opportunities for businesses and individuals to widen their reach in the burgeoning manufacturing sector.

In line with the rapid adoption of Industry 4.0 technologies, the UAE is also strengthening partnerships among industry, academia and various vocational training programmes, in collaboration with global tech companies, to help bridge any skills gap and ensure a seamless transfer of the latest technological knowledge to the UAE workforce.

Today, the UAE’s manufacturing sector stands at a pivotal juncture. With the UAE's emphasis on attracting investments and prioritising inclusivity, innovation, and sustainability, the country is laying the foundation for long-term industrial leadership.

Alongside policy support, the UAE's strategic location and rapidly improving infrastructure position it as a rising global manufacturing hub.

Manufacturing is no longer just a supporting act in the UAE’s economic story. It’s now a lead character that plays a vital role in shaping a resilient, innovative, and sustainable future for the country.

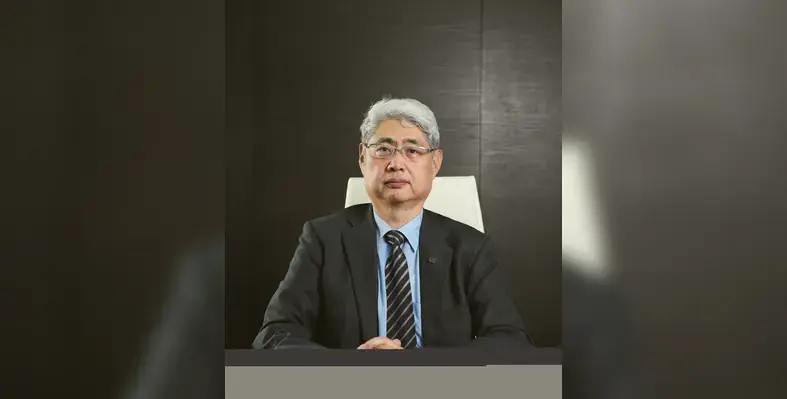

By Noritsugu Mifune, CEO, Al Gharbia Pipe Company

Wirtgen to unveil new technologies at Conexpo 2026

Wirtgen Group and John Deere are set to make a major impact at Conexpo 2026, unveiling six market premieres and three global firsts alongside a broad portfolio of advanced machines, automation systems and digital solutions

With a total of 24 world and market premieres on display, the joint exhibition will focus on boosting productivity, transparency and profitability across road construction, earthworks and materials processing.

Visitors to the shared stand (Silver Lot SV2415) will experience a construction site-centric showcase, including a dedicated presentation of the John Deere Operations Center located on the ground floor of the Innovation Center. Designed as a central digital hub, the platform consolidates machine, job and performance data in one place. The exhibit will also highlight a comprehensive suite of digital aftermarket solutions on the upper floor.

A total of 14 Wirtgen Group machines will feature the latest automation and data-driven technologies, including the Wirtgen Group Performance Tracker combined with solutions such as AutoPilot 2.0, Smart Level Pro, Smart Pave, Smart Compact Pro and SPECTIVE CONNECT. These technologies automate workflows while capturing and analysing performance data, enabling more efficient, transparent and cost-effective execution across every phase of the construction process.

Global firsts and market premieres

Cold milling specialist Wirtgen will introduce a world premiere that opens up an entirely new application area for customers, with full details to be revealed at the start of the exhibition. Also on display will be the new WR X-Tier generation of wheeled cold recyclers and soil stabilisers. These machines cover applications ranging from structural road rehabilitation to soil stabilisation and material consolidation in road construction.

The WR X-Tier series features an intuitive Human-Machine Interface (HMI) that provides interactive digital guidance to improve mixing quality and productivity. Digital assistants such as MIX ASSIST and Wirtgen Group COPILOT further enhance efficiency while reducing operating costs per square metre.

Vögele will debut the latest Dash 5 paver generation for the North American market, offering improved operator ergonomics, faster setup, higher automation levels and a more efficient drive system. Key highlights include world premieres in the 10 ft class: the SUPER 2000-5 X tracked paver and the SUPER 2003-5 X wheeled paver, both equipped with newly developed screeds. The range is complemented by the SUPER 2100-5 X, featuring a high-compaction screed suited for roller compacted concrete applications.

In the Mini Class segment, Vögele will present the SUPER 800-5 P, the successor to the SUPER 700. This compact Dash 5 paver introduces the ErgoBasic 5 operating concept and a redesigned hopper wall geometry that improves visibility and loading flexibility. All Dash 5-X-Tier pavers can be fitted with the latest digitalisation and automation solutions.

Automation and precision compaction

Hamm will focus on automated compaction technologies, highlighting enhancements to the Smart Compact system. Smart Compact Pro now integrates real-time asphalt density measurement through the new Realtime Density Scan function, enabling automated adjustment of compaction energy and modes on HD+ and HX series tandem rollers. Operators can monitor density development in real time across the entire jobsite, including during static compaction.

This capability supports precise compliance with specifications, reduces the risk of penalties and lowers overall project costs while contributing to longer pavement service life. Hamm will also introduce solutions for earthworks, including automated amplitude adjustment based on new measurement values, and a new compactor model designed specifically for the North American rental market.

Materials processing and digital connectivity

For materials processing, Kleemann will present the MOBISCREEN MSS 1102 PRO scalper, making its North American debut. Designed for quarry applications, the PRO Line screening plant handles throughput of up to 750 t/h and features an intuitive control system that minimises operating errors and training time. Remote operation enhances safety, while the optional Dual Power drive allows for all-electric operation.

Kleemann screening plants can now be equipped with SPECTIVE CONNECT, providing operators with real-time machine data via smartphone. The integrated stockpile monitoring function offers clear visibility of material status, improving productivity and site coordination.

John Deere Operations Center as the digital backbone

At the core of the digital offering is the John Deere Operations Center, which brings together all data required for end-to-end construction site management. Project data can be transferred directly to machines via the integrated Work Planner, enabling partially automated execution. Users gain continuous insight into project progress through performance data generated by Wirtgen Group Performance Tracker solutions covering milling, paving, compacting, crushing and stabilising.

With smart hardware and software, existing machines can be quickly retrofitted to capture and document performance data. These digital solutions help contractors meet reporting requirements with minimal additional effort, reducing administrative burden while streamlining daily operations.

GDS Middle East drives manufacturing innovation through digital design

As manufacturing across the GCC accelerated towards digitalisation, advanced design and engineering software becomes central to competitiveness. GDS Middle East has played a pivotal role in supporting local manufacturers to modernise product development, engineering workflows and production processes.

In an exclusive interview with Technical Review Middle East, director Jimmy Joseph highlighted the company's main offerings, which include bespoke solutions for the manufacturing sector.

The company enables local firms to shorten product development cycles by facilitating the adoption of tools such as Solidworks, Catia, Enovia and Simulia.

These are platforms which, according to Joseph, allow engineering teams to iterate designs more quickly, test and optimise solutions early in development, and respond faster to market demands.

“These technologies allowed engineering teams to test, refine and optimise designs early in the development phase, which significantly reduced time to market,” he said.

Solutions such as Solidworks Sheet Metal Design also help manufacturers optimise material usage and streamline production processes, reducing waste and lowering costs.

GDS additionally supports firms seeking differentiation through customisation, allowing manufacturers to meet specific client requirements and target niche markets.

But this is not the company's only offerings.

Training and upskilling forms a core part of GDS Middle East’s approach.

Joseph highlighted the importance of capability building, explaining that “technology alone does not deliver results. It is about enabling engineers and designers to use these tools effectively, and that comes through hands-on training and ongoing support.”

How can automation help?

Industry insights and analytics provided by GDS further helps manufacturers align their product strategies with market trends, improving efficiency, productivity and competitiveness across the region.

Digital tools also reshaped engineering workflows. Platforms such as Solidworks PDM and Enovia, deployed either on premise or via the 3D Experience cloud platform, enabled real-time collaboration across teams and stakeholders, regardless of location.

Automation through tools like DriveWorks allowed repetitive tasks to be handled efficiently, freeing engineers to focus on complex design and innovation.

Data-driven features and AI-enabled analytics provided insights that helped optimise both processes and products.

Simulation tools such as Abaqus and Solidworks Simulation accelerated development by allowing virtual testing and validation before production, reducing time, costs and risk.

Generative design and additive manufacturing added additional efficiencies by creating optimised, material-efficient designs.

GDS Middle East also addressed the challenges manufacturers faced in adopting new software.

But there are challenges ahead

Resistance to change, integration with existing systems, skill gaps and high initial investment costs were common barriers.

Joseph noted that the company worked closely with clients to demonstrate the long-term value and ROI of technology adoption, and that “annual subscription offerings from Dassault Systèmes help customers reduce the initial cost drastically and absorb it into operating budgets.”

Tailored solutions and ongoing technical support ensured firms could continue optimising their workflows.

Looking ahead, Joseph believes the greatest opportunities for design software lay in streamlining the entire manufacturing lifecycle.

“Advanced design and analysis tools can streamline the design process through simulation, reducing time-to-market and enabling faster iterations and modifications,” he said.

Cloud-based collaboration facilitates communication across dispersed teams, generative design enables customised products, and integration with manufacturing execution and ERP systems creates connected workflows that reduce errors and enhance efficiency.

GDS Middle East positions itself not simply as a software provider but as a technology implementation partner.

A fully integrated platform

Its end-to-end approach—from collaboration and design to manufacturing and dispatch—combined with in-house technical expertise and continuous support, allows manufacturers in the GCC to adopt, integrate and benefit from digital tools effectively, improving competitiveness in an increasingly digital industrial landscape.

As Joseph puts it, “GDS Middle East is uniquely positioned to seize new opportunities in the GCC by serving as a true technology implementation partner rather than just a product supplier.”

He adds that his company's skilled in-house technical team “sets us apart in the region, allowing us to support clients beyond the sale with hands-on customization, training, and continuous support. In short, GDS captures opportunities by being the partner that helps customers implement and succeed with technology, every step of the way.”

Fuelre4m fuel treatment improves efficiency across UAE fleets

UAE-based fuel technology company Fuelre4m has announced new results showing its fuel treatment can deliver consistent fuel efficiency and emissions reductions across buses, trucks, and heavy equipment operating in real-world conditions.

Independent testing led by the National Technical University of Athens (NTUA), one of Europe’s leading engineering and applied sciences universities, evaluated Fuelre4m’s technology under tightly controlled laboratory conditions using a commercial diesel engine running on standard B10 biodiesel. The tests recorded 3.5–6.7% lower fuel consumption at identical engine speed and mechanical torque, alongside consistent efficiency improvements of 15–21% in the dominant mid-load operating range of approximately 1,400–1,550 RPM.

“The laboratory result establishes a conservative baseline under fixed torque, while real-world operation allows the same efficiency improvement to reduce torque demand, improve gear behaviour, and compound over time, resulting in larger total fuel savings across a complete duty cycle. Crucially, the only variable introduced during testing was the treatment of the fuel itself, with no changes to engine hardware, electronic calibration, operating limits, or fuel specification,” Fuelre4m said.

The NTUA laboratory findings are now being reinforced by repeatable real-world trials across UAE transport and industrial fleets. These include city and intercity buses operating on Dubai service corridors, mixed fleets incorporating VDL and King Long buses, and heavy trucks and off-highway equipment operating under high-load conditions. Once sufficient fuel contact time is achieved, measured fuel efficiency improvements frequently match or exceed laboratory results. Fixed-route trials on UAE buses show directional fuel consumption reductions of approximately 14–17%, with the strongest improvements consistently appearing in the mid-RPM “working bands” that dominate urban and intercity duty cycles.

Trials were conducted across mixed fleets spanning multiple manufacturers, engine sizes, and emission standards, confirming that the benefits are not limited to a single platform or technology generation. No adverse impacts were observed on drivability, engine temperatures, or aftertreatment systems. Quarry and heavy-equipment trials, including large off-highway haul trucks, demonstrated reduced fuel consumed per unit of work, with several recording double-digit efficiency improvements while maintaining or increasing productivity.

Commenting on the findings, George Papalambrou, Associate Professor of Control Systems at NTUA, who oversaw the independent testing, said, “We were genuinely surprised by the consistency and magnitude of the mid-range efficiency improvements. The results were not isolated to a single operating point and were observed under multiple control regimes. This is a positive development not just for one sector, but potentially for all industries relying on internal combustion engines, including shipping and maritime transport.”

Rob Mortimer, CEO of Fuelre4m, said, “For decades, the industry has optimised engines around the assumption that fuel behaviour is fixed. These results show that when you improve how fuel behaves, efficiency and emissions improve immediately, using the engines already operating across the UAE today.”

Fuelre4m is expanding controlled in-service validation programmes across the UAE in collaboration with fleet operators, government entities, and industrial partners. These programmes will focus on high-utilisation routes, long-duration performance validation, and quantified emissions reduction under representative operating conditions. Further independent testing using fully instrumented dynamometer facilities is also planned to extend validation into transient operation and regulatory-grade certification environments.

Parsons opens Doha office to support Qatar infrastructure

Parsons Corporation has officially opened its new regional office in Doha, marking a significant expansion of the company’s footprint in Qatar and reinforcing its long-term commitment to supporting national development priorities.

The office was inaugurated by Carey Smith, chair, president, and chief executive officer of Parsons Corporation. The event was attended by senior representatives from the U.S. Embassy Doha, Qatar’s Public Works Authority, Qatari Diar, the American Chamber of Commerce Qatar, alongside Parsons’ regional leadership team and employees.

Located in Al Emadi Financial Square, the new Doha office will serve as a regional design hub for Parsons’ expanding portfolio of infrastructure design, urban development, mobility and programme management projects across Qatar. The facility is intended to enable closer collaboration with clients, project teams and stakeholders as major infrastructure and development programmes across the country continue to progress.

“Parsons’ growth in Qatar underscores the company’s outstanding reputation in the Middle East, our position as a trusted partner to our customers, and our competitive advantage in the region,” said Smith. “For more than two decades, we’ve proudly partnered with important customers across Qatar to deliver on some of the nation’s most prominent and vital infrastructure projects. Expanding our physical presence in Doha strengthens our ability to deliver complex, mission-critical programmes with speed and agility. This expansion strengthens our regional presence and global capabilities, and highlights the important role our thriving Middle East portfolio plays in the company’s continued global success.”

Parsons has maintained a presence in the Middle East since the 1950s and brings extensive regional expertise across project and programme management, urban development, transportation and master planning. Its capabilities span rail and metro systems, aviation, roads and ports, smart mobility solutions, asset management and large-scale urban development programmes.

In Qatar, Parsons has played a key role in delivering sustainable infrastructure and smart city initiatives aligned with the country’s long-term vision for growth. The company has contributed to several landmark national projects, including the FIFA World Cup Qatar 2022, Seef Lusail Development, Al Khor Expressway, Lusail Light Rail Transit, Doha Metro networks and the expansion of Hamad International Airport.

The new Doha office builds on Parsons’ more than 25-year track record in Qatar, during which the company has supported transportation planning, expressway programmes, major roadway and drainage systems, as well as programme, construction management and advisory services for national infrastructure initiatives.

The office will host multidisciplinary teams supporting a pipeline of ongoing and upcoming projects across Qatar, positioning Parsons to respond efficiently to future opportunities while continuing to deliver complex infrastructure programmes that support economic growth and urban development in the country.