COBOD International, in partnership with Technische Universität Braunschweig, has launched the first commercially available multifunctional construction robot, expanding the scope of 3D printing in construction.

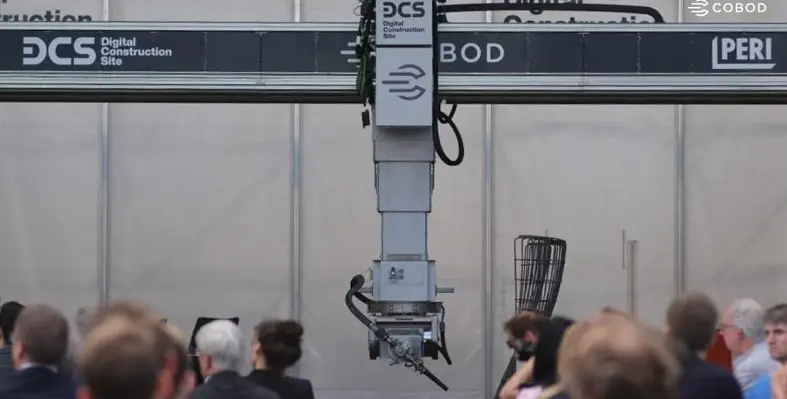

Unveiled during the grand opening of the Digital Construction Site at TU Braunschweig, the system merges COBOD’s BOD2 3D construction printer with a telescopic vertical extension and robotic arm designed for the Shotcrete 3D Printing Process (SC3DP).

Shotcrete, a concrete-spraying technique typically used in complex structures such as tunnels, retaining walls, and swimming pools, forms the basis of the SC3DP system.

However, the telescopic unit’s versatility allows it to host multiple tool types beyond shotcrete, including sanding equipment, paint spray guns, and insulation tools, transforming the 3D printer into a multifunctional robotic platform.

A 3D printing aid

The system offers a dynamic vertical reach of 3 metres, enabling the robotic arm to operate on printed structures situated up to 3 metres below the X-axis.

This functionality allows users to print, reinforce, and finish complex, double-curved concrete walls with precision and geometric freedom. Reinforcement can either be embedded after concrete placement or applied by spraying around prefabricated reinforcement meshes.

The launch was attended by Helga Kühnhenrich, Head of Research and Innovation in the Construction Industry at Germany’s Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR), who highlighted the growing industry focus on automation to cut costs and reduce labour dependence.

According to COBOD, the robotic system can even be equipped with a gripper to automatically install prefabricated elements such as aerated concrete blocks or bricks, features traditionally outside the scope of standard 3D printing setups.

With this, the company aims to redefine what construction robotics can achieve, merging digital precision with functional adaptability.

Henrik Lund-Nielsen, general manager and founder of COBOD International, said, “For years we have had the vision of making multifunctional construction robots on the basis of our 3D construction printers. Seeing the first materialisation of our vision here makes me very proud. With this new technology we offer automation of many more construction processes than just printing of concrete walls. With our new COBOD robotic arm at the end of the telescopic arm there is an endless amount of construction tasks that our printing system can now automate and expedite to the benefit of our global customers.”

Professor Harald Kloft for Structural Design at ITE explained, “Our partnership with COBOD is a decisive step towards the digital construction site of the future. 3D printing enables automated, digitally controlled processes of simple as well as very complex tasks, like the fabrication of reinforced double curved walls. The ability to make complex, individualised, material efficient and low waste construction solutions makes 3D printing ideal for the construction industry, as it brings together economic, environmental and social aspects, such as the reduction of physical stress.”

Also read: Volvo CE excavators undergo rigorous testing; outperform rivals