Kyocera has unveiled innovative tooling solutions to achieve high-performance cut-off solutions and strong clamping mechanism, increasing safety and security

The MFWN miniseries is a smaller version of the original cutters, which also offer excellent performance and tool life.

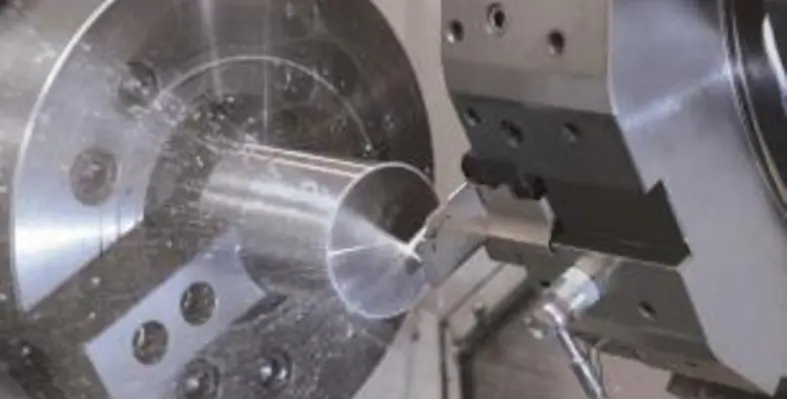

According to Kyocera, when it comes to cutting operations in general, the workpiece can be difficult to secure which leads to rigidity and chattering issues. Therefore, the cutting speed is usually low at the workpiece rotation centre. Also, tools tend to be broken easily by chip troubles. All these issues are long gone with the KPK series as it features a new insert, blade and a tool block design for rigid, safe and speedy cut-off operations in the fields of steel, stainless steel, cast iron and aluminium. Due to the easy insert replacement, the down time is reduced to a minimum. The firmly secured insert uses three contact surfaces to ensure safe clamping which eliminates chattering completely and makes the cutting-off process a lot safer.

The chipbreaker technology is inherited from the KGD lineup and provides excellent chip control. Thanks to this advanced technology the tool life is longer and the machining stable. The rigid tool holder block not only prevents chattering but also provides an internal coolant which again adds to the tool life even under normal pressure.

Kyocera?s new line is based on the original, the MFWN milling cutter, but is in no way inferior to it. On the contrary, the mini series works at up to five mm D.O.C., while the large model can be used at a cutting depth of up to eight mm. This product is also used for machining materials such as steel, stainless steel, cast iron and exotic materials.

The design is based on the original MFWN series with fracture-resistant inserts, low cutting forces and neutral inserts for various uses. Another plus is the insert lineup. It is comprehensive for various machining applications. In total there are three insert chipbreakers and four grades available.