European Union Stage V emissions standards introduced may raise questions for original equipment manufacturers (OEMs) and their customers

Stage V regulations set strict limits on particulate matter (PM) emissions for nonroad mobile machinery (NRMM), requiring 19 kW to 560 kW (25 hp to 751 hp) engines to be fitted with wall flow particulate filter technology. With new technologies come more questions about complexity, performance, ease of use, maintenance, and total cost of ownership.

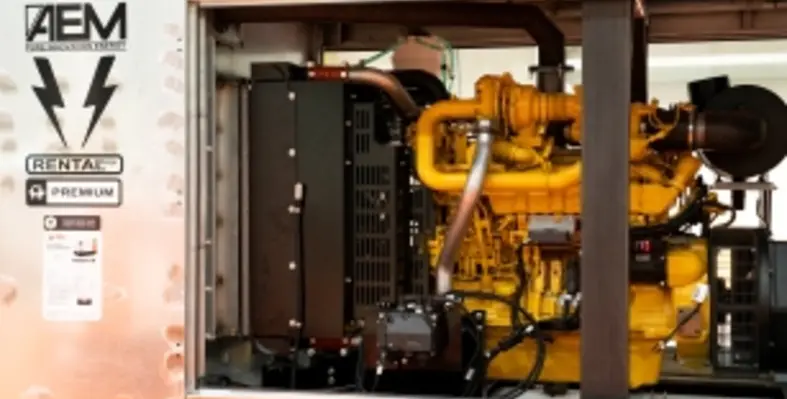

Spanish generator set manufacturer Alternativas Energ?ticas Murcia S.L. (AEM Spain) took the lead to inform equipment rental companies with a dedicated Stage V event. At the event, a John Deere team provided integration support and a Stage V power unit for AEM?s prototype 200kVA generator set. John Deere has accumulated more than one billion hours of operating experience with exhaust filters, which includes this AEM prototype.

Support at every stage

As an engine and machine manufacturer, John Deere can leverage the remarkable global experience gained since first introducing aftertreatment technology to meet Interim Tier 4/Stage III B regulations in 2011. John Deere Power Systems (JDPS) continues to develop proven emissions solutions for OEM customers. This expertise played a key role in AEM?s decision to collaborate with JDPS on its prototype 200kVA Stage V generator set. For the prototype, Transdiesel, JDPS distributor for Spain, Portugal, and Morocco, supplied a PSS 6.8L power unit. A few months before the unit arrived, Transdiesel engineers visited AEM to provide its engineers and sales managers preliminary training on the aftertreatment system. Before integration, Transdiesel shared several configurations of the aftertreatment system for the 200kVA generator set, and engineers were present throughout tests and final calibration. While adding the new system required internal design changes, the impact on the overall weight and size of the generator set was minimal. ?Integrating the new aftertreatment system throughout our range may become a complex exercise, so we are pleased being able to work with Transdiesel,? says AEM?s Antonio Matteo.

At its Stage V event, AEM introduced the prototype 200kVA generator set to its customers. In live presentations, AEM, JDPS, and Transdiesel engineers outlined Stage V advantages such as optimised uptime, performance, and fuel efficiency. The 75plus companies that attended could also gather more information on the technology. The 200kVA Stage V prototype is the first of many to come for AEM. Transdiesel general manager J?r?me Zanon commented: ?We are grateful for the trust AEM has put in us and are pleased that the JDPS Stage V engines let us offer one of the most advanced technologies on the market.?

At its Stage V event, AEM introduced the prototype 200kVA generator set to its customers. In live presentations, AEM, JDPS, and Transdiesel engineers outlined Stage V advantages such as optimised uptime, performance, and fuel efficiency. The 75plus companies that attended could also gather more information on the technology. The 200kVA Stage V prototype is the first of many to come for AEM. Transdiesel general manager J?r?me Zanon commented: ?We are grateful for the trust AEM has put in us and are pleased that the JDPS Stage V engines let us offer one of the most advanced technologies on the market.?