Multiphase pumping is an economic solution for ageing oilfields, where, over time, the natural reservoir pressure drops off to a point where some wells lose the ability to overcome the back pressure generated by the surface flow lines and the first stage separator of the process facility

The conventional alternatives considered by operators are increasing the flow line size and the installation of a significantly lower pressure first stage separator that would be significantly larger. These alternatives have been carefully reviewed. However, the costs and necessary permissions by the appropriate authorities have proven to be significant and not economical.

Engineering technologies company, Leistritz, specialises in multiphase pumping solutions for oilfields. Leistritz had initialised a project study in 2015 with its client to draw down the back pressure on the producing wells with the help of a multiphase wellhead pumping system to about 200 psig, which would allow the wells to produce oil and gas at an acceptable rate.

To overcome the flow line pressure including some reserve, the pressure boosting of the multiphase pump had to be around 500 psi in order to reach the line back pressure of 700 psig.

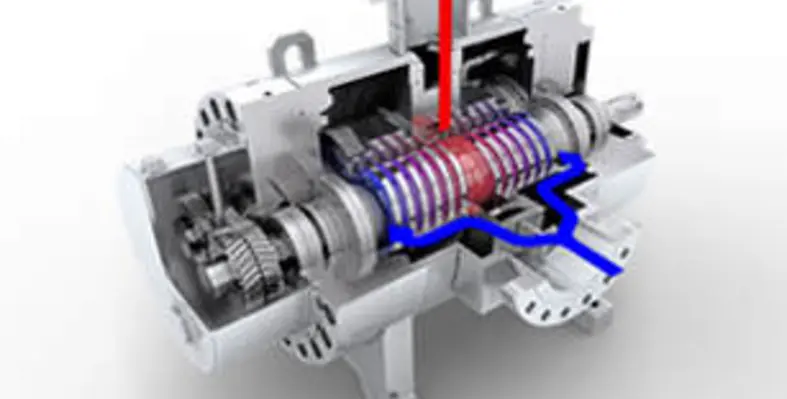

The multiphase wellhead system (Model L300) based on the Leistritz twin-screw pump was selected, proposed and purchased in the summer of 2015.

The system had to be designed for remote unmanned operation and the outside of power supply had to be completely self-supporting. Remote access of the operating parameters was achieved over the internet by a secure access for the operator as well as for Leistritz.

The liquid rates could vary between 300 to 1,000 bpd and gas rates between 0.5 and one million standard cubic feet per day. The combined flow rate at pump inlet conditions would be between 6,000 and 14,000 boepd (barrels of oil equivalent per day) corresponding to a GVF (gas void fraction) around 95 per cent. The flow regime was expected to be slug flow and heavy slugs could affect the multiphase pump unit. In order to seal and protect the pump and remove the heat of compression from the pump a recirculation system was included, designed to gather liquids in a knock-out boot or separator downstream of the pump and circulate some of the liquids back to the pump suction. This system would assist the pump and provide the liquids necessary to maintain compression even during longer gas slugs.

Other design features included a VFD controlled 400 HP 1800 RPM electric motor and a double mechanical seal system with the API Plan 54 seal flush. The complete unit with piping, valves, instrumentation and controls was designed and manufactured in the Leistritz facilities.

Installation and commissioning of the system took place in Q2 2016. The unit has performed as expected and adding significant production for the operator. This case study points to the opportunities using multiphase pumping in lieu of other back pressure reducing alternatives.

The multiphase pump together with VFD speed control has proven its flexibility to instantly adapt to actual field conditions and to optimise production with lower flowing wellhead pressure.