Zebra Technologies, a provider of digital solutions that enable businesses to intelligently connect data, assets, and people, announced that TAS, a global supplier to automotive OEMs, has enhanced the production quality of electric vehicle battery caps.

This improvement was achieved using a reliable and precise deep learning machine vision solution powered by Zebra’s Aurora Vision Studio software, ensuring greater accuracy and security in the manufacturing process.

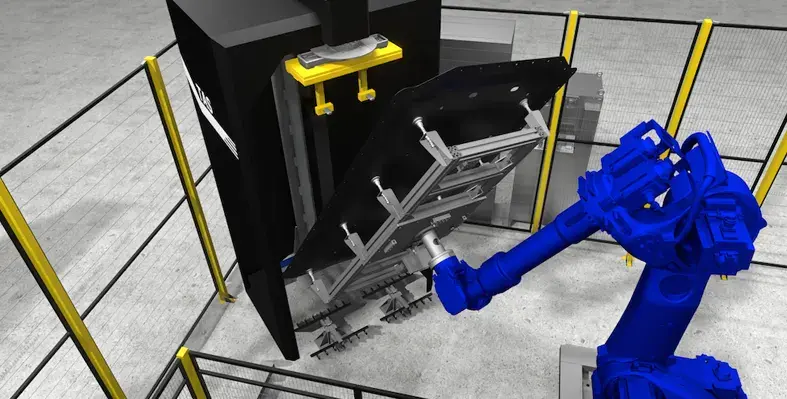

To ensure precise finishing for each battery cap, TAS employs a meticulous process where robotic systems handle the metal sheets through various inspection stages. A highly sophisticated camera system is utilised to detect potential defects that could affect quality.

Custom-built operations

This custom-built camera system, designed by ID Engineering, a Zebra Registered Industrial Automation System Integrator specialising in machine vision, can identify even the smallest surface imperfections, ensuring the caps' safety and performance.

The adaptability of Aurora Vision Studio enhances the system's reliability, allowing TAS to continuously improve safety and precision by addressing coating irregularities, surface scratches, and laser marking issues.

Setting itself apart from other solutions, the Aurora Vision Studio system integrates deep learning tools that drive continuous improvement throughout the manufacturing process. The system is trained using a comprehensive dataset of images, enabling it to recognise and classify specific defect types. These image datasets are annotated and fed into the system, which can be retrained to identify new inspection criteria or fine-tuned for existing defects. This allows the image processing solution to evolve and improve continuously, leveraging deep learning technology.

A key advantage of this deep learning capability is its flexibility, ensuring reliable inspection even when industrial conditions change—a significant benefit over traditional image processing tools, which may not adapt well to evolving production environments. The system’s flowchart-based image processing solution uses a no-code approach, enabling fast and convenient training, ensuring that TAS maintains consistent product quality while adapting to production changes.

“The successful integration of surface treatment technology and a custom-built quality control system with deep learning represents a significant advancement in quality control and our continuous commitment to innovation,” said Temel Tas, managing director, TAS. “With Zebra Technologies’ machine vision system, we can meet the high-quality standards of the automotive industry, and we are already planning to implement this technology in future projects.”

“The main advantage of Zebra’s Aurora Vision Studio is its speed in development and execution time when analysing many and sometimes large image files simultaneously, which is much faster than other technologies we tested,” said Michael Sartor, machine vision department head, ID Engineering. “The scalable Zebra system is easy to use and it’s no-code solution enables fast development. Beyond the technology, we appreciate the valuable support from Zebra.”

“This solution is a good example of how deep learning algorithms can be used to help ensure better quality in industrial production,” said Donato Montanari, vice president and general manager, Machine Vision, Zebra Technologies. “Aurora Vision Studio and its deep learning add-on provide the foundation on which even huge amounts of data can be processed and utilised. This is an important contribution to the manufacturing technology of the future.”