Ducab, a leading UAE-based manufacturer of high-quality cables and energy solutions, has achieved a major technical milestone with the Middle East’s first Extended Pre-qualification (EPQ) test for an Extra-High Voltage (EHV) 400kV cable system at 105°C emergency temperature.

The achievement, completed in collaboration with Swiss specialist Brugg Cables, reinforces Ducab’s reputation for technical excellence and positions the company for global expansion.

The EPQ and system type test represents a regional first and demonstrates Ducab’s ability to meet the most stringent international standards, including IEEE, IEC, and AEIC. The testing was conducted in partnership with Brugg Cables, a recognised leader in high-voltage accessories; TAQA, Abu Dhabi’s government-controlled energy holding company; and DEKRA, the world’s largest independent testing, inspection and certification organisation.

“This successful Brugg test cements Ducab’s reputation for technical leadership and innovation, opening new opportunities in Europe,” said Charles Edouard Mellagui, CEO of Ducab Cables Business. “We are delighted to accelerate our efforts to take our quality HV cables from the UAE to the world.”

The collaboration offers strategic advantages for Ducab, which is now the only supplier on TAQA’s vendor list with two approved accessory suppliers – SEI and Brugg Cables. The EPQ milestone enhances Ducab’s competitiveness for EHV cable system projects across the region and internationally, enabling faster, more effective service for TAQA, regional utilities, and new clients in Europe and the US.

Gianluca Vettese, CEO of Brugg Cables, said: “We are proud to support Ducab in achieving this significant EPQ test, highlighting the strength of our technical collaboration and our shared commitment to delivering world-class high-voltage cable systems that meet the highest international standards.”

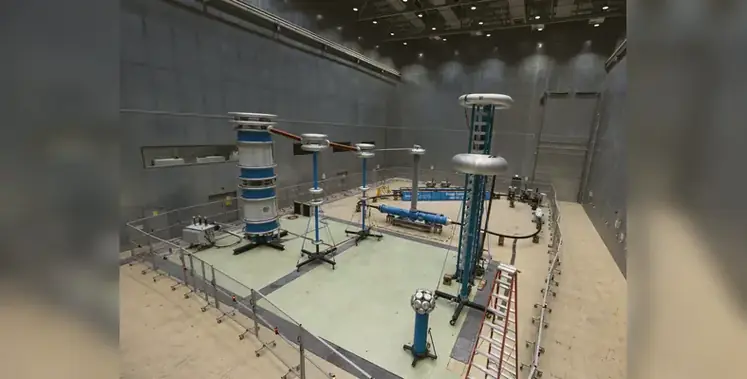

Brugg Cables’ specialised testing services for HV and EHV cables, up to 550kV, incorporate a large Faraday cage and on-site diagnostics to ensure insulation integrity and performance. Key elements of the testing process include AC voltage tests, partial discharge measurements for joints, and sheath testing, all designed to ensure reliable, long-term operation of high-voltage cable systems.

With this milestone, Ducab strengthens its technical leadership in the Middle East and sets the stage for international growth, offering utilities and industrial clients high-quality, globally certified EHV cable solutions.