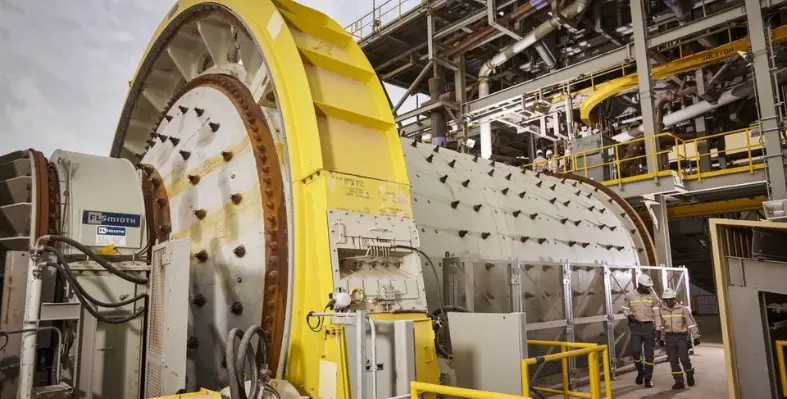

Every year on 28 August, the UAE celebrates Emirati Women’s Day. (Image source: Al Gharbia Pipe Company)

Every year on 28 August, Emirati Women’s Day honours the achievements of women across the UAE who are contributing to national progress. This year, three young Emirati engineers at Al Gharbia Pipe Company reflect on how they are shaping the country’s industrial future through innovation, technology, and a passion for lifelong learning. Sania Aziz writes.

For Azeeza Al Ali, innovation engineer at Al Gharbia Pipe Company, integrating artificial intelligence into manufacturing is not just about efficiency. It is about aligning with the UAE’s wider industrial ambitions. “At Al Gharbia Pipe Company, we’ve integrated AI through smart systems like MES 4.0 to monitor production in real time, reduce downtime, and cut waste,” she explains. “AI also powers our automated quality checks and helps optimise energy and material use, supporting both efficiency and sustainability in line with UAE’s industrial goals.”

Azeeza Al Ali, innovation engineer at Al Gharbia Pipe Company

Yet the journey has not been without challenges. Azeeza notes that the lack of in-house AI expertise often requires relying on external partners. “One key challenge is that we don’t have in-house AI specialists, so for every AI idea, big or small, we need to find and work with external vendors. This takes time and coordination,” she admits. “But by choosing the right partners and starting with AI projects, we’ve been able to move forward in line with the UAE’s digital transformation goals.”

Her colleague, Meera Mansour Al Bloushi, has taken a more hands-on route in the company’s innovation drive. As assistant engineer – innovation, she built a vision-guided autonomous robot from scratch, an achievement that brought together engineering disciplines and underscored her commitment to sustainability. “The goal was to build a robot that could detect and pick up objects mainly for recycling and sorting materials like paper, plastic, and general waste using a camera, image processing, and precise motor control,” she says.

Meera Mansour Al Bloushi, assistant engineer – innovation, Al Gharbia Pipe Company

Although her background is in electrical work, Meera took on the mechanical design herself. “I designed the robotic arm and assembled the parts, and ensured smooth operation by integrating stepper motors, sensors, and programming the movement logic. The camera allowed the robot to ‘see’ and respond to its surroundings in real time,” she explains. In an industrial setting, she believes robots like this can “help improve efficiency and safety by automating tasks such as sorting, inspection, and material handling in hard-to-reach areas, as well as support sustainability efforts.”

Her curiosity, however, extends beyond robotics. A passionate advocate of lifelong learning, Meera continues to explore new areas that feed into her ambition of becoming a researcher and inventor. “I’m currently exploring new skills outside my main field, such as CNC turning, web application development, and electrical installation,” she says. “Even though these areas seem different, they help me grow as a well-rounded researcher and inventor. I believe being an engineer isn’t about staying in one narrow field – it’s about having broad knowledge and curiosity.”

For Mahla Mohamed Almansoori, another assistant engineer – innovation at Al Gharbia, technical competitions were the starting point of her career. She honed her skills in CNC milling while competing at the Emirates Skills National Competition, an experience that taught her the value of precision and perseverance. “My CNC milling experience and success at Emirates Skills taught me to work with precision, think creatively under pressure, and solve problems step by step,” she reflects. “At Al Gharbia, I use this mindset to find practical and efficient solutions to meet and elevate our high quality standards.”

Mahla Mohamed Almansoori, assistant engineer – innovation, Al Gharbia Pipe Company

Now, she is applying that same discipline to rethinking industrial workflows. “I’m working on making manufacturing data cleaner and faster to use by automating processes and reducing manual work,” Mahla says. “I’m also improving workflows to cut waste and boost productivity, helping support the UAE’s vision for a smarter and stronger industrial sector.”