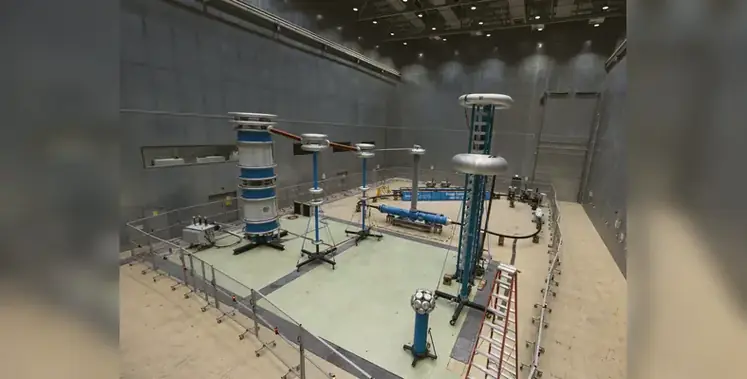

The exhibition will cover six core product groups spanning the full lifecycle of process industries. (Image source: ACHEMA)

Saudi Arabia’s expanding industrial and energy transition ambitions are set to gain a new international platform with the launch of ACHEMA Middle East, scheduled to take place from 26-28 October 2026 at the Riyadh International Convention & Exhibition Center.

The inaugural regional edition of the long-established ACHEMA exhibition comes as the Kingdom accelerates large-scale projects aimed at decarbonisation and advanced manufacturing. These include a major carbon capture hub in Jubail, designed to capture up to nine million tonnes of CO2 annually by 2028, and the US$8.4bn NEOM Green Hydrogen Project, which targets the production of 600 tonnes per day of clean hydrogen by 2027.

Held under the patronage of the Saudi Ministry of Industry and Mineral Resources and supported by ASAS, the event is organised by Messe Frankfurt and powered by DECHEMA. The exhibition extends ACHEMA’s century-long legacy in chemical engineering and process industries into the Middle East, Africa and South Asia (MEASA) region.

For more than 100 years, ACHEMA has served as a global meeting point for the chemical, pharmaceutical, biotechnology and laboratory sectors. Its debut in Riyadh is intended to connect international technology providers with regional manufacturers, policymakers and researchers at a time when Saudi Arabia is pursuing industrial diversification under Vision 2030.

Exhibition main themes

The exhibition will cover six core product groups spanning the full lifecycle of process industries, including industrial engineering, laboratory and analytical solutions, automation and digital systems, packaging and supply chain technologies, and research and development. Organisers say the integrated scope reflects the increasingly interconnected nature of modern industrial operations.

Conference programming will centre on six innovation themes: process, pharma, lab, digital, green and energy innovation. CPD-accredited sessions and expert-led discussions will address topics such as electrification, bioprocessing, artificial intelligence-enabled operations and circular economy models.

Dr Björn Mathes, chief executive of DECHEMA Exhibitions, described the Riyadh edition as a strategic evolution. “By bringing ACHEMA to Riyadh, we are creating a platform where science, engineering and industrial innovation align with the ambitions of one of the world’s most dynamic industrial economies,” he said.

Azzan Mohammed, managing director of Messe Frankfurt Saudi Arabia, said the event would foster knowledge exchange and support the development of sustainable and competitive industrial ecosystems.

Early confirmed exhibitors include Yokogawa, GMM Pfaudler, Hach, Beckhoff, Aptek, Pharmadule Morimatsu, Tofflon and Sealmatic, signalling strong international interest ahead of the show’s first edition.