Bentley Systems, Incorporated, the infrastructure engineering software company, announced at COP27 expanded integrated workflows for embodied carbon calculation in the Bentley iTwin platform

The new integration enables carbon assessment in infrastructure digital twin solutions, empowered by the Embodied Carbon in Construction Calculator (EC3). Developed by the non-profit Building Transparency, EC3 is a no-cost, open-access tool that allows benchmarking, assessment, and reductions in embodied carbon, focused on the upfront supply chain emissions of construction materials. Building Transparency provides the education, resources, and tools – including EC3 – to address embodied carbon’s role in climate change.

Rodrigo Fernandes, Bentley’s director of ES(D)G, said, “This new integration in Bentley’s infrastructure digital twin platform exemplifies our strategy for empowering our users to achieve sustainable development goals. EC3 from Building Transparency is a perfect example of purpose-driven open, ecosystem collaboration, by which the private sector can come together to support and accelerate climate action.”

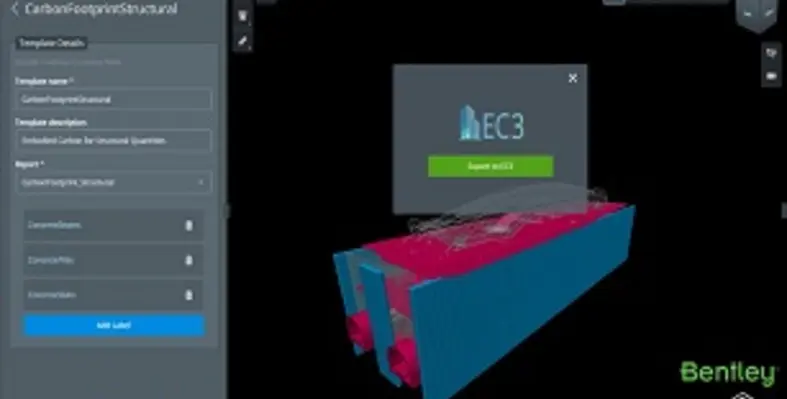

The EC3 integration allows Bentley’s infrastructure digital twin solutions, powered by iTwin, and third-party applications built on the Bentley iTwin platform, to simplify and accelerate the generation of carbon reporting and insights based on the no-cost, open-source EC3 carbon database and calculator. The Bentley iTwin platform is an open, scalable, platform-as-a-service offering that enables developers to create and bring to market solutions that solve real infrastructure problems by leveraging digital twins.

“Microsoft was the first large corporate user of the Embodied Carbon in Construction Calculator and is piloting the tool (hosted in Microsoft Azure) on its 17-building redevelopment project at its headquarters in Redmond, Washington, targeting an embodied carbon reduction of 30%. We are proud to be one of the early supporters of EC3, and simultaneously, strategic partners of Bentley Systems,” said Katie Ross, global sustainability lead for real estate and facilities at Microsoft. “Seeing the EC3 tool and the Bentley iTwin platform converging is a great example of how we aim to accelerate sustainability through collaboration and demonstrates the power of data democratisation.”

A significant amount of time is spent assessing or reporting on the environmental footprint of infrastructure projects, mainly when manually exporting and aggregating data from quantity counts and bills of materials. It can also be error-prone, requiring additional verification of successful ingestion by carbon tools. Moreover, AEC professionals do not want to be locked into one single carbon calculator as different calculators may provide different results, and carbon reporting and certification requirements differ as a function of the project, country, or infrastructure owner.

The added integration with EC3 both creates time savings with improved accuracy, and provides uncertainty estimations of the EPD data and increases carbon transparency due to Building Transparency’s open-source/open-access strategy. Users can incorporate engineering data created by various design tools into a single view using the Bentley iTwin platform, generate a unified report of materials and quantities, and share it with different carbon analysis tools – now also with EC3 – via cloud synchronisation.

“For WSP, carbon footprint analysis and reduction are imperative in planning, designing, building, and operating an infrastructure project from beginning to end,” said Thomas Coleman, vice president of WSP USA. “Enabling better iTwin integration with EC3 is game-changing for us on multiple infrastructure projects. Implementing this link will significantly reduce the time and cost of generating EC3-based detailed embodied carbon analysis and reports along the design and construction stages.”