Volvo Penta has introduced the G17 natural gas engine, expanding its power generation portfolio with a solution designed to support fuel flexibility, lower emissions and resilient energy systems as the global energy transition accelerates.

The G17 is the natural gas counterpart to Volvo Penta’s established D17 genset engine and forms part of the company’s wider transformation journey. Designed to meet rising demand for dependable and lower-emission power, the engine offers a pathway for customers seeking to decarbonise operations without compromising on performance or reliability.

“The energy transition isn’t one-size-fits-all,” says Kristian Vekas, Product Manager for Industrial Power Generation at Volvo Penta. “It requires multiple technologies and fuel pathways working in parallel. The G17 expands our power generation portfolio with a gas option engineered to meet rising global demand for dependable, lower-emission solutions that are backed by the strength of the Volvo Group and our global support network. It reflects our commitment to providing customers with fit-for-purpose solutions to support their energy objectives as the landscape continues to evolve.”

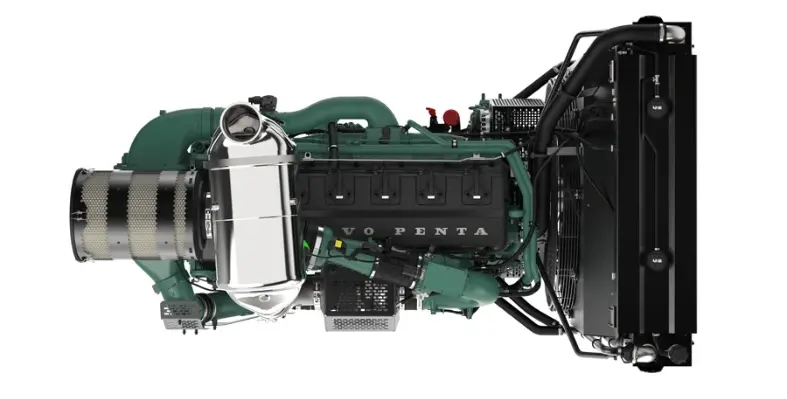

Built on the same heavy-duty platform as the D17, the G17 is a 17-litre, six-cylinder, spark-ignited engine capable of operating on both pipeline-quality natural gas and renewable natural gas. This dual-fuel capability allows operators to reduce carbon intensity while maintaining uptime, durability and responsiveness in mission-critical applications.

“The G17 is engineered to deliver lower emissions without trade-offs,” says Kristian. “Its flexible fuel capability helps reduce carbon intensity while maintaining the power density, responsiveness and durability customers expect from Volvo Penta’s heavy-duty platform.”

Engineered to deliver approximately 450 kWe at 1,800 rpm, the G17 provides high power output from a compact footprint. Its smaller enclosure enables reduced installation space and lower housing material costs, while fast load acceptance supports reliable performance during demand surges or grid transitions. The engine’s pipeline-ready design allows direct connection to existing gas infrastructure, simplifying installation and removing the need for additional fuel-conditioning systems.

The G17 has been developed to deliver reduced emissions of nitrogen oxides and particulate matter. Advanced combustion controls, low-pressure Exhaust Gas Recirculation (EGR) and a high-efficiency three-way catalyst enable compliance with US EPA stationary power application standards, positioning the engine as a viable option for operators with strong ESG targets or operations in air quality-sensitive zones.

Its compact, stackable platform makes the engine well suited for space-constrained environments such as data centres. It can also be integrated into hybrid energy systems that combine internal combustion engines, renewable fuels and battery storage, enabling scalable and adaptable power architectures.

Supported by Volvo Penta’s global dealer network, the G17 is intended to deliver long-term performance and reliability. “With the G17 gas engine, Volvo Penta is expanding its ability to deliver integrated energy solutions that combine proven technology, emerging fuel pathways and strong service,” Kristian concludes.