KOHLER-SDMO has expanded the top end of the KD Series with the rollout of new models 4000kVA and 4500kVA (50Hz) / 3500kW and 4000kW (60Hz), based on a strong worldwide market response

In late 2016, KOHLER-SDMO unveiled an entirely new range of large diesel industrial generators up to 2800kVA (50Hz) / 2500kW (60Hz) powered by a newly designed platform of KOHLER diesel engines represented by the K135 and K175 engine families. The range was subsequently extended to 3500kVA (50Hz) / 3250kW (60Hz) in 2018.

The new generators are designed to deliver extreme durability and ultimate reliability in a variety of emergency and prime applications. This release expands the limits of standby generators and sets KOHLER apart with its breadth of product in this range.

Brad Meissner and C?dric Briand, product managers at KOHLER , said, ?With a 4500KVA / 4000kW generator, KOHLER can now offer customers the largest and most power-dense standby generator in the marketplace.?

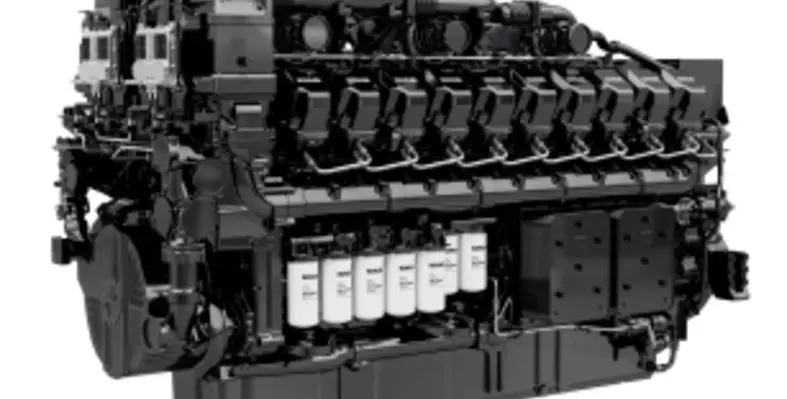

Developed by the company?s global team of engineers, the new KD Series up to 4500kVA and 4000kW gensets incorporate a powerful and sophisticated K175 diesel engine ? the KD 103 litre, 20-cylinder model. From a design perspective, KOHLER kept many of the engine components the same as the KD Series predecessors including the control system, fuel system, and cooling system, to name a few.

The modular design of the KD103V20-powered generator sets is a bit larger than its V16 and V12 counterparts and delivers unprecedented power density and unrivaled performance.

Matched turbochargers are engineered for maximum power and response. High ambient cooling systems ensure performance is maintained in the most extreme environments. The engine features a high-pressure common rail, precise fuel injection system that delivers pressures up to 2200 bars. Fuel mapping options for optimised fuel consumption for use in non-emissions regulated regions, emissions optimised for use in Europe, the USA, Canada, etc or low-NOx optimised for use in mission critical segments like data centres enable the generators to be deployed globally without worry. Users of the KD Series generators will find cost savings because the offering delivers top-of-the line fuel consumption regardless of the calibration. To reduce noise and vibration, the engines have a closed-loop regeneration crankcase ventilation system and rigid block, crankcase and sub-frame.

The generators are equipped with the APM802 controller that ties the entire system together for a seamless customer experience. The APM802 control unit provides enhanced performance and monitoring features such as (+/-.25%) voltage regulation, expanded inputs and outputs, a large twelve-inch color touchscreen, and the ability to parallel as many as thirty-two generator sets.