Brady has developed a reliable solution to automate printed circuit board (PCB) identification processes on surface-mount technology (SMT) lines in order to save time and increase efficiency

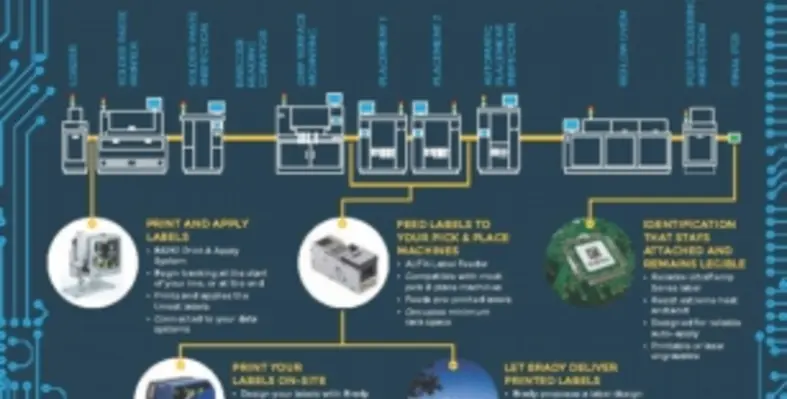

Know how practical integration of automated PCB identification can be done simply. See the infographic.

Complete and fully automated traceability labelling

Brady presents a complete traceability solution that can connect every circuit board in production to a smart factory set up. With Brady's solution, circuit boards can generate data and send these to a manufacturing execution system, to other machines and production cycles, or to the supply chain both upstream and downstream.

Brady's reliable printed circuit board labels are designed for auto-apply and can keep 2D codes and barcodes legible in PCB manufacturing conditions so they can be read by scanners throughout a production process.

A fully automated printed circuit board labelling solution can enable traceability and manufacturing data analysis without human interference. Brady can offer several automation solutions depending on the needs of an organisation.

Visit Brady booth in Hall 2 #305 at PRODUCTRONICA 2019 from 12-15 November in Munich.