The secure supply of electricity is crucial for the reliability of systems, data centres and buildings

A failure of electricity is not necessarily caused by the user or the infeed. The path from the generator to the system harbours risks that should be kept in mind for a secure energy supply. Short circuit protection is critical for system availability even after the actual event. Standard-compliant measures for cable installation offer more security.

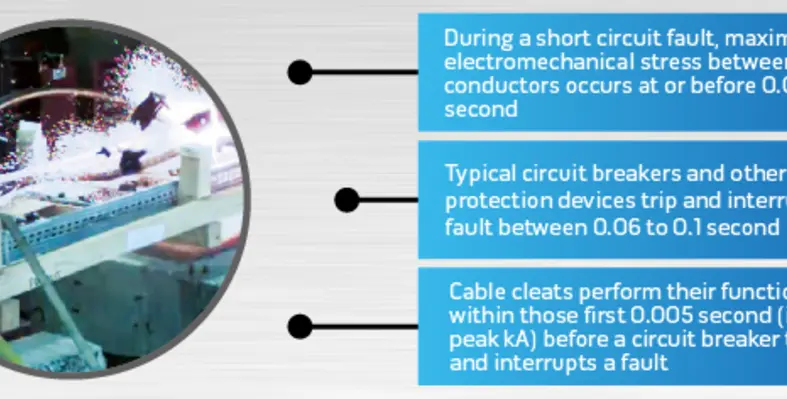

An electrical short circuit leads to a massive increase in current flow through low and medium voltage cables in just a few milliseconds. The amperage can be up to 200,000A during such events. The increased current flow and the resulting magnetic field around the cable create dynamic forces through the interaction of 50 Hz. As a result, the cables are made to vibrate. In the worst case of a three-phase short circuit, the magnetic field-induced impact forces between the cables can be up to 45,000 N and develop within 1/100 of a second. Significant damage can occur before the circuit breakers can trip on the short circuit. As a result, cable retention is critical to protecting personnel and infrastructure, as well as reducing downtime.

These dynamic forces are absorbed by the cable cleats and the associated cable support system. The cable cleats, which are attached to the support system, prevent individual cables from being torn loose by the vibration and damage to system parts, and the electrical installation. Nevertheless, in new or existing systems, the apparently fast, but poor way of fastening cables is unfortunately being sought. It is relatively easy to use a professional and safe installation solution.

These dynamic forces are absorbed by the cable cleats and the associated cable support system. The cable cleats, which are attached to the support system, prevent individual cables from being torn loose by the vibration and damage to system parts, and the electrical installation. Nevertheless, in new or existing systems, the apparently fast, but poor way of fastening cables is unfortunately being sought. It is relatively easy to use a professional and safe installation solution.

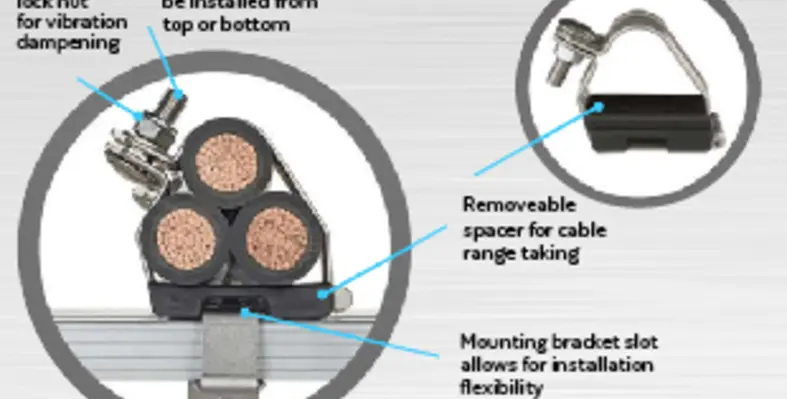

The new cable cleats from Panduit vary in size, design and materials and are suitable for a wide variety of applications in process engineering systems, information technology and industrial production. There is a choice of materials for the various applications, aluminum, plastic and corrosion-resistant, dual-certified stainless steel 316 / 316L. Stainless steel cable cleats have folded and rounded edges so that they do not damage the cables. The buckle has its own cable holder and can accommodate cables in four-leaf and clover-leaf formations as well as multi-core cables.

Once the cables are in place, the cable cleat can be attached using a mounting bracket that is unique in the industry. The bracket can be tensioned and cut to length with a hand-operated ratchet installation tool or a tool for tightening a tensioning screw. The ties are often used in conjunction with a damping sleeve inserted between the tie and the cable to provide additional protection. A plastic buckle is available for stainless steel cable ties as well as various mounting brackets. As an example, stainless steel cable cleats are available for cable diameters from 12 to 86 mm in widths from 12.7 to 19.1 mm for short circuit currents from 45 to 188 kA. Of course, tools for professional and quick installation are also available.

Benefits of cable cleats in accordance with IEC 61914: 2015:

- User-friendly and professional cable installation

- Risk reduction in the event of a short circuit by absorbing static, mechanical, and dynamic forces

- Protection of people and system components

- Securing the energy supply

Learn more about Panduit Cable Cleats: https://solutions.itrident.com/panduit-cable-cleat-solutions-tr-2022