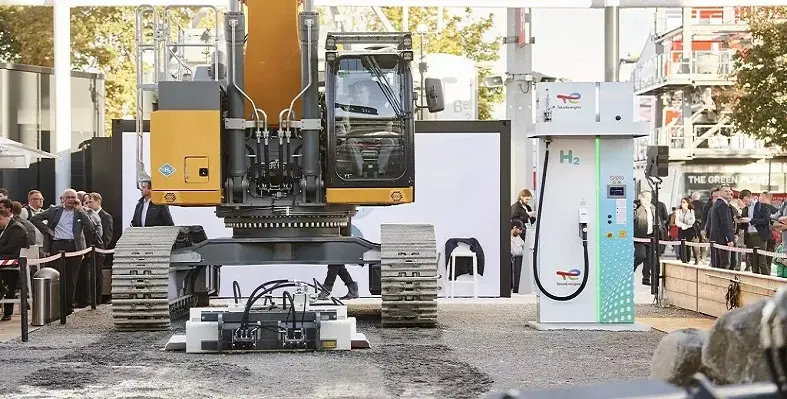

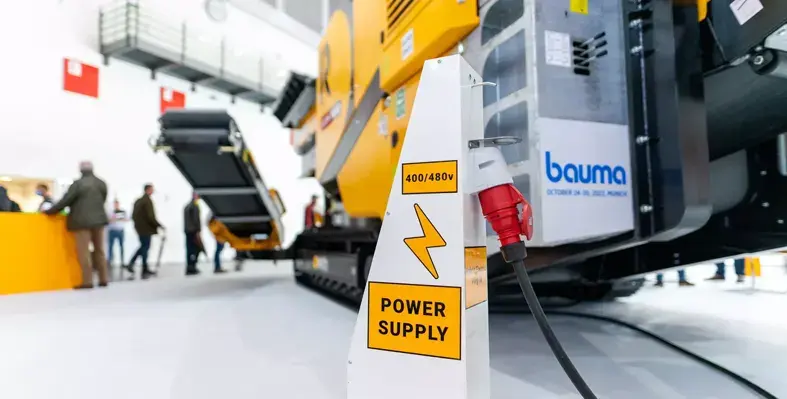

bauma, one of the world’s leading construction and mining machinery trade fairs that is run on a three-ear cycle, is returning 7-13 April 2025 at the Trade Fair Center Messe München, Germany

This year, the event is looking to answer how construction processes be as climate-neutral as possible in the future, a pertinent topic in the modern age as the world strives to reach net zero goals.

A statement from bauma has outlined some of the key areas progress can be made, and where the event in Germany will focus on:

• Process automation: “As the international construction machinery industry has already been vigorously driving forward this development for decades, for example, through increasingly economical components, much has already been achieved in this regard,” said Joachim Schmid, managing director in the construction machinery and building material plants division at the German Mechanical Engineering Industry Association (VDMA).

• Digitalisation: At bauma, opportunities around digitalisation and automation will be clear with digital solutions enabling better planning of machines. Developing more sophisticated machine-to-machine communication can ensure more efficient production chains, while smart sensors can monitor machine status. These are but some of the advantages being realised which bring tangible benefits such as avoiding idle times and increasing energy consumption.

• Alternative drive concepts: In addition to the use of electric motors, many companies are focusing on developing and testing hydrogen-power construction machinery. Such concepts – in addition to alternative fuels like HVO – have great potential for reducing greenhouse gases. “Because alternative drive concepts are currently so relevant for manufacturers and users, we are dedicating a separate key topic to this technology segment at bauma 2025,” surmised Nicole Schmitt, bauma exhibition director.

• Continuing the conversation: According to the bauma organisers, to make sure a transformation to climate-neutral construction succeeds, then discussions between industry stakeholders need to be maintained. At bauma, machine manufacturers, construction companies, politicians, researchers, and everything in-between will be represented and encourage to partake in the dialogue and drive the industry forward.

In The Spotlight

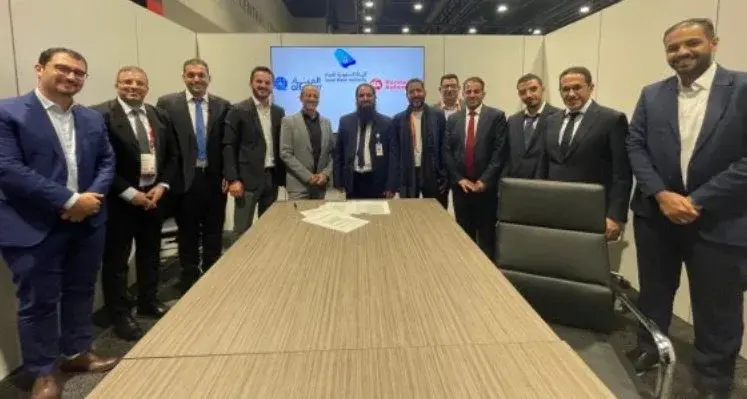

The Wirtgen Group has announced the appointment of Panafrican Equipment Group as its new authorised dealer, expanding access to its complete line of products and technologies across Kenya, Tanzania, Uganda, Rwanda and Burundi in East Africa, as well as Ghana and Sierra Leone in West Africa

In Nigeria, the partnership will specifically cover the group’s minerals and soil compaction portfolio.

A long-standing partner across Africa

For decades, the Wirtgen Group has maintained a strong presence on the continent. Its six specialist brands – Wirtgen, Vögele, Hamm, Kleemann, Benninghoven and Ciber – work in synergy to meet the specific requirements of customers across diverse sectors. Together, they bring proven expertise and extensive industry knowledge to African markets. “With the innovative road construction and mineral solutions, the Wirtgen Group is well equipped to meet future challenges”, says Jerry Muchiri, Manager Regional Business and Dealer Development East Africa and Nigeria at Wirtgen International GmbH.

Panafrican’s strong after-sales commitment

Panafrican’s established footprint and its commitment to high-quality service delivery will further strengthen access to Wirtgen Group’s technologies throughout the region. “As authorised dealer, Panafrican provides complete support for all construction and mineral processing needs, combining our service expertise with Wirtgen Group's innovative portfolio and applications know how,” commented Scott McCaw, CEO and managing director Panafrican Group.

The collaboration positions both companies to deliver enhanced customer support and reinforces their shared dedication to innovation, quality and customer-centric service.

Get a real-time list of equipment present in a vehicle and see what is missing versus an established vehicle equipment list. Select missing tools on-screen. Quickly home in with proximity-increasing sounds and visuals on a portable RFID reader

Discover the affordable RFID Scan & Drive solution from Brady!

Have you ever arrived at an intervention without the necessary equipment? Ever lost tools during field interventions? How much time do you spend to make sure all equipment is accounted for, and present in your vehicles? Now you can confirm vehicle inventories digitally and automatically, highlight any missing assets, and home in on misplaced items to quickly complete your vehicles. How much time could you save?

Everything present

Instantly see which tools are present in a vehicle - and what is missing. Easily save substantial time per vehicle, per intervention, with automated equipment inventory checks that take only seconds.

By labelling equipment with passive, battery-free UHF RFID labels, we can let an RFID reader in your vehicle detect which tools and items are present. The RFID reader can check detected tools versus a list of expected items to confirm a complete vehicle inventory or to highlight missing equipment on your phone.

Be fully equipped before leaving for a field intervention. Avoid losing tools after interventions. Don’t waste time checking visually where every piece of equipment is. Just scan, get confirmation in seconds, and drive to your next destination.

Home in on assets

Quickly find misplaced equipment. Home in on specific items with a portable RFID reader and proximity-increasing sounds and visuals.

Passive, battery-free UHF RFID labels bounce back radio signals from a portable RFID reader up to 15 metres. By measuring the strength of the returning radio signal with patented data capture technology, our portable RFID readers guide users towards a unique RFID label applied on a specific tool. When closing in, auditive and visual feedback strength from the reader increases.

RFID labels can include an LED, powered by an RFID reader from a 1.5 metre distance, to let a tool light up or to find it in a dense inventory of equipment.

Solution components

Brady develops and manufactures every component in our solution. Tested in in-house laboratories, each component is designed to withstand the wear and tear of field interventions, including exposure to UV, dust and moisture.

- RFID labels: Brady offers industrial grade on- and off-metal RFID-labels and tags that stay attached and remain legible on your equipment.

- Fixed RFID readers: Equipped with patented data capture technology, Brady’s fixed RFID readers collect data on items passing through their read range.

- Portable RFID readers: With intuitive displays, Brady’s portable RFID readers and SLEDs deliver unmatched mobility, data collection and interaction.

Are you interested in automated inventory checks solution from Brady? Visit our website, watch the short video and download the free RFID labelling guidebook.

.The museum stands as a profound tribute to the life, leadership, and legacy of the late Sheikh Zayed bin Sultan Al Nahyan.(Image source: EMSTEEL)

EMSTEEL has announced its pivotal contribution to the construction of the iconic Zayed National Museum—the newest cultural beacon in Abu Dhabi’s Saadiyat Cultural District.

Officially inaugurated by the UAE President, His Highness Sheikh Mohamed bin Zayed Al Nahyan, and attended by Their Highnesses the Supreme Council Members and Rulers of the Emirates, the opening formed part of the nation’s celebrations for the 54th Eid Al Etihad. The museum stands as a profound tribute to the life, leadership, and legacy of the late Sheikh Zayed bin Sultan Al Nahyan, embodying the UAE’s unity, heritage, and ambitious future.

Throughout the museum’s development, EMSTEEL played a central role by supplying the structural backbone of this architectural masterpiece. Across three years, the Group delivered approximately 24,000 tonnes of rebar, up to 25,000 direct block units, and around 100,000 tonnes of bulk cement. These critical materials underpinned the engineering integrity of the project, enabling the creation of a landmark that will serve as a cultural touchstone for generations to come.

Saeed Ghumran Al Remeithi, group CEO of EMSTEEL, said,“The opening of the Zayed National Museum on the 54th Eid Al Etihad is a defining moment for our nation. It reflects the vision of the late Sheikh Zayed bin Sultan Al Nahyan and the unity that shaped the UAE’s extraordinary journey of progress. As a national industrial champion, we are honoured that our steel and building materials contributed to a landmark of such cultural and historic significance. This project reflects our role in supporting the UAE’s long-term development and our commitment to fostering an industrial sector that continues to strengthen the nation’s future.”

EMSTEEL’s involvement in the Zayed National Museum adds to its impressive legacy of supporting the UAE’s most celebrated cultural and architectural undertakings. From Louvre Abu Dhabi and the Natural History Museum Abu Dhabi to the upcoming Guggenheim Abu Dhabi, along with national treasures such as Sheikh Zayed Grand Mosque and Dubai’s Museum of the Future, the Group has become synonymous with high-impact, visionary development.

These landmark contributions underline EMSTEEL’s position as a trusted partner in national progress. With an unwavering focus on sustainability, low-carbon manufacturing, and resilient local supply chains, EMSTEEL continues to bolster the UAE’s industrial strength while helping shape its cultural and architectural legacy.

Italian shipbuilder Fincantieri and ASRY (Arab Shipbuilding & Repair Yard) have signed an Memorandum of Understanding (MoU) to explore new opportunities for collaboration in the shipbuilding sector

Under the MoU, the two sides will jointly evaluate opportunities for the design and construction of offshore service and military vessels up to 80 metres in length, as well as the potential for export contracts in the Gulf area.

The agreement also includes maintenance, repair, and overhaul (MRO) services for military, commercial and offshore vessels, as well as the exchange of know-how in naval design and production process optimisation.

The military vessels would be intended for use by the Bahrain Navy and Coast Guard.

ASRY is a leading operator in ship repair and marine services in the Gulf of Bahrain.

Fincantieri was represented by its chairman, Biagio Mazzotta, and Eugenio Santagata, general manager of the Fincantieri Naval Vessels Division, who signed the agreement together with Ahmed AlAbri, CEO of ASRY.

Pierroberto Folgiero, CEO and managing director of Fincantieri, said the MoU represents an opportunity for Fincantieri to enter the Bahraini shipbuilding market and is a further step in consolidating the group's strategy and presence in the Middle East.

“This agreement strengthens our strategic position in the Gulf and confirms Fincantieri's desire to develop long-term industrial partnerships with leading partners such as ASRY,” said Folgiero.

“By combining complementary skills and converging visions, we are laying the foundations for a solid and structured presence in the Bahraini shipbuilding market, in line with the objectives of our integrated export platform in the Middle East.”

The signing of the MoU took place on the sidelines of the 46th Gulf Cooperation Council Summit in the presence of Italian President of the Council of Ministers Giorgia Meloni, and Bahrain’s Crown Prince and Prime Minister His Royal Highness Salman bin Hamad Al-Khalifa.

Separately, Fincantieri announced a partnership In Saudi Arabia with King Abdullah University of Science and Technology (KAUST) to establish a scholarship aimed at supporting young researchers in maritime security, cyber-resilience and emerging applied navigation technologies.

It follows an MoU signed last January and reflects a shared commitment of both sides in promoting excellence in education and technology transfer, in line with Saudi Arabia’s Vision 2030, a Fincantieri statement read.

“The scholarship will enable young and talented researchers to develop innovative solutions to counter new threats to navigation, such as recent cases of AIS and GPS spoofing, which can alter vessel positions and compromise the safety of shipping routes,” it stated.

The programme will focus on three strategic areas: the advanced authentication of AIS signals to prevent manipulation; the opportunistic detection of GPS spoofing through intelligent satellite data analysis, and star-based position verification enhanced by machine learning algorithms.

Fincantieri added that the goal is to develop an operational software platform that can be integrated into on-board digital systems, strengthening the collaboration between universities and industry and contributing to the growth of the Fincantieri Digital Ecosystem (FDE).

IEA reports 76 million employed in energy sector in 2024, but skilled labour shortages pose challenges

Significant global investment in energy infrastructure drove a 2.2% rise in energy-sector employment last year, nearly double the rate of job growth in the broader world economy, according to a new IEA report

The World Energy Employment 2025 report, released today, shows that the global energy workforce reached 76 million in 2024, an increase of over five million roles since 2019. Over the last five years, the energy sector has contributed 2.4% of all net new jobs created worldwide.

The power sector has been a key driver of this growth, accounting for three quarters of recent employment gains and now ranking as the largest employer in energy, overtaking fuel supply. Solar PV remains a major driver, complemented by expanding employment in nuclear power, electricity grids, and energy storage. As electrification spreads across industries, roles in EV manufacturing and battery production surged by nearly 800,000 in 2024.

Fossil fuel employment remained resilient throughout the year. Coal-sector jobs rose in India, China, and Indonesia, lifting coal employment 8% above 2019 levels despite sharp declines in advanced economies. The oil and gas industry has regained most of the jobs lost in 2020, although low prices and economic uncertainty have triggered some workforce reductions in 2025. Early data suggest that overall energy-sector employment growth may moderate to 1.3% this year, as tight labour markets and geopolitical tensions prompt caution among employers.

Despite the sector’s strong growth, the report highlights a worsening shortage of skilled workers. More than half of the 700 companies, unions, and training institutions surveyed through the IEA’s Energy Employment Survey reported critical recruitment bottlenecks that could delay infrastructure projects, slow major initiatives, and increase system costs.

“Energy has been one of the strongest and most consistent engines of job creation in the global economy during a period marked by significant uncertainties,” said IEA executive director Fatih Birol. “But this momentum cannot be taken for granted. The world’s ability to build the energy infrastructure it needs depends on having enough skilled workers in place. Governments, industry and training institutions must come together to close the labour and skills gap. Left unaddressed, these shortages could slow progress, raise costs and weaken energy security.”

Technical and applied roles such as electricians, pipefitters, line workers, plant operators, and nuclear engineers are particularly hard to fill. These occupations have added 2.5 million jobs since 2019 and now represent more than half of the global energy workforce, more than double their share of total employment across the wider economy.

Demographic pressures are also intensifying. In advanced economies, 2.4 energy-sector workers are nearing retirement for every new entrant under 25. Nuclear and grid-related professions face some of the steepest ageing challenges, with retirement-to-new-entrant ratios of 1.7 and 1.4 to 1, respectively.

At the same time, the supply of newly trained workers is insufficient to meet demand. To prevent the skills gap from widening by 2030, the number of new qualified energy workers globally must increase by 40%. Achieving this would require an additional US$2.6bn per year, less than 0.1% of total global education spending.

The report stresses that policy action can help address these challenges. Respondents identified training costs, foregone wages, and limited awareness of programmes as major barriers to entry. Effective measures include financial incentives for learners, expanded apprenticeship schemes, increased private-sector participation in curriculum design, and investment in training facilities. Reskilling within the sector is also essential. While some regions are already seeing declines in fossil fuel employment, targeted retraining programmes could help workers transition to fast-growing areas of the energy system.

Soudah Development, a Public Investment Fund (PIF) company, has announced a project to deliver advanced power infrastructure to its Soudah Peaks development

The company signed an agreement with National Grid, a subsidiary of the Saud Electricity Company, valued at more than SAR 1.3bn (US$346mn), to develop and deliver power systems for its luxury mountain-based resort.

The company said in a statement that the strategic partnership marks a “critical milestone” in the development of Soudah Peaks.

Its project is described as an ultra-luxury mountain destination in Saudi Arabia, rising 3,015 metres above sea level.

Under the agreement, National Grid will design and construct the integrated electrical network that includes a 380/132 kV central substation with a capacity of 500 MVA, as well as two 132/13.8 kV high-voltage substations.

This infrastructure will form the backbone of the utility ecosystem across all zones of the project, ensuring reliable power delivery to hospitality, residential, commercial, and public assets, for all development phases.

“This agreement represents a pivotal milestone in developing the electrical infrastructure for the Soudah Peaks project,” said Eng. Waleed Al-Saadi, CEO of the National Grid SA.

“It reflects our firm commitment to supporting major development initiatives in the kingdom through integrated solutions built on the highest standards of efficiency and reliability.”

Al-Saadi also said that the partnership with Soudah Development underscores its central role in enabling luxury tourism destinations and the kingdom’s growing economic landscape.

“By establishing an advanced electrical network tailored to meet the project’s needs across all phases, we reaffirm National Grid SA’s continued efforts to enhance the readiness and resilience of the power system in alignment with sustainability goals and Saudi Vision 2030.”

Eng. Saleh Al-Oraini, CEO of Soudah Development, said it marks a defining step forward in the journey to develop Soudah Peaks.

“Through our partnership with National Grid SA, we are securing the infrastructure foundation needed to power all of Soudah Peaks development phases.”

HRH Prince Mohammed bin Salman announced the launch of Soudah Development Company (SDC) in 2024, with plans to attract over two million visitors annually and create 8,000 direct and indirect permanent jobs by 2030.

Read more:

ACWA Power closes major Saudi renewables deal

IEA reports faster global progress on energy efficiency in 2025

Siemens Energy has named Hussein Shoukry as the new managing director for the Middle East and Africa. He takes over from Dietmar Siersdorfer, who is retiring after an impressive career spanning nearly four decades with the company.

Based in the UAE, Hussein will oversee Siemens Energy’s operations and strategic initiatives across a regional network of 29 offices, employing more than 4,000 people and generating EUR 9 billion in order intake in fiscal year 2025.

“Rising energy demand is reshaping the future of both the Middle East and Africa,” Hussein said. “In the Middle East, countries are embracing a diversified energy mix and building localized supply chains, while in Africa the priority is expanding reliable electricity access for millions. The region also includes markets where critical energy infrastructure is being rebuilt or modernized.”

He added, “With our broad portfolio in energy technology and long-standing presence, Siemens Energy will remain a committed partner in meeting these needs and strengthening the resilience of the Middle East and Africa’s energy systems.”

Hussein brings extensive experience in managing complex energy projects and enhancing global execution capabilities. Since joining Siemens Energy in 2003, he has held multiple leadership roles, most recently as Senior Vice President for Project Execution, where he led a team of over 3,500 employees and managed the company’s global Competence Centers in Romania, Mexico, and India.

Holding a degree in Construction Engineering from the American University in Cairo, Hussein’s engineering background, project execution expertise, and deep understanding of diverse energy markets across Europe and the Middle East equip him to lead Siemens Energy’s business in the Middle East and Africa effectively.

Siemens Energy has named Hussein Shoukry as the new managing director for the Middle East and Africa. He takes over from Dietmar Siersdorfer, who is retiring after an impressive career spanning nearly four decades with the company.

Based in the UAE, Hussein will oversee Siemens Energy’s operations and strategic initiatives across a regional network of 29 offices, employing more than 4,000 people and generating EUR 9 billion in order intake in fiscal year 2025.

“Rising energy demand is reshaping the future of both the Middle East and Africa,” Hussein said. “In the Middle East, countries are embracing a diversified energy mix and building localized supply chains, while in Africa the priority is expanding reliable electricity access for millions. The region also includes markets where critical energy infrastructure is being rebuilt or modernized.”

He added, “With our broad portfolio in energy technology and long-standing presence, Siemens Energy will remain a committed partner in meeting these needs and strengthening the resilience of the Middle East and Africa’s energy systems.”

Hussein brings extensive experience in managing complex energy projects and enhancing global execution capabilities. Since joining Siemens Energy in 2003, he has held multiple leadership roles, most recently as Senior Vice President for Project Execution, where he led a team of over 3,500 employees and managed the company’s global Competence Centers in Romania, Mexico, and India.

Holding a degree in Construction Engineering from the American University in Cairo, Hussein’s engineering background, project execution expertise, and deep understanding of diverse energy markets across Europe and the Middle East equip him to lead Siemens Energy’s business in the Middle East and Africa effectively.

In a strategic move advancing the UAE’s sustainability agenda, ServeU LLC, the facilities management subsidiary of Union Properties PJSC, has entered a partnership with PureBlue Water, a Dutch specialist in decentralised wastewater treatment technologies

The collaboration aims to deploy advanced distributed water treatment systems across residential, commercial, industrial, and leisure developments throughout the UAE.

ServeU brings its extensive regional presence and integrated facilities management capabilities, while PureBlue Water contributes its compact, high-efficiency treatment modules designed to operate at source rather than rely on large centralised sewer networks. These systems bypass extensive pressurised pipelines and traditional large-plant infrastructure, offering faster deployment, reduced construction and maintenance costs, and enhanced operational efficiency. The treated effluent is suitable for reuse on-site, such as for irrigation of golf courses, rooftop gardens, and shaded community spaces, thereby conserving freshwater resources and promoting greener landscapes.

Aligned with the UN Sustainable Development Goals and the UAE’s climate action objectives, this initiative underscores a shift toward circular economy water management and sustainable infrastructure delivery. ServeU’s commitment to embedding sustainable solutions across its operations is reinforced through this venture, as the company accelerates its transformation into a provider of smart, environmentally conscious built environment services.

Together, ServeU and PureBlue Water are delivering a model for the future, where modern infrastructure supports efficient water reuse, cost-effective operation, and the creation of sustainable ecosystems across the UAE’s built environment sectors.

Mohamed Amer, managing director of ICC MENA, highlights how GCC nations are integrating transparency, verification, and sustainability across construction, materials, and urban development.

Across the Gulf Cooperation Council (GCC), from the dynamic skylines of Riyadh and Dubai to the UAE and Saudi Arabia’s ambitious net-zero strategies, the region is constructing a future-oriented built environment while setting global benchmarks

As governments, developers, and manufacturers embrace more responsible building practices, one principle is becoming increasingly critical: transparency is emerging as the cornerstone for credible sustainability initiatives.

In a region where development is rapid and ambitions are vast, this shift toward transparent sustainability is both timely and necessary.

From vision to verification

National strategies such as Saudi Arabia’s Vision 2030 and the UAE’s Net Zero 2050 Strategy place environmental stewardship at the centre of economic transformation. These are not mere symbolic gestures but structural commitments aimed at securing a sustainable future.

Governments and designated demand drivers are establishing measurable, time-bound targets. For instance, the UAE’s Federal Decree Law requires companies emitting 500,000 tons or more of carbon dioxide annually to monitor and report greenhouse gas emissions. These metrics ensure accountability through verified progress, with commitments being evidenced and enforced.

Construction firms and other stakeholders are expected to substantiate sustainability goals with certifications, lifecycle assessments, and emissions data. Authorities are increasingly mandating environmental product declarations and embodied carbon thresholds, aiming to confirm that buildings are efficient and resilient. Embedding transparency throughout the construction lifecycle—from design and procurement to operation and decommissioning, enhances accountability and ensures tangible results.

Sustainable construction requires measurable change

According to a PwC report, sustainable technologies in the built environment could reduce lifecycle emissions by more than 50% across the MENA region. Meeting this challenge demands a fundamental transformation in how buildings are designed, sourced, constructed, and operated.

Material selection is therefore crucial, and maintaining traceability throughout the supply chain is a top priority. While low-carbon concrete, recycled steel, and bio-based alternatives are increasingly accessible, independently verified data is essential to ensure that these choices achieve the intended outcomes.

The International Code Council (ICC) supports the creation of compliance ecosystems grounded in science, transparency, verifiability, and enforceability. The International Codes® (I-Codes) assist jurisdictions in adopting actionable sustainability frameworks that provide enforceable standards, clear guidance, and measurable results. The ICC’s solutions ranging from training and certification to product testing, accreditation services, and digital compliance tools offer a comprehensive pathway to help stakeholders implement sustainability objectives effectively. A robust compliance ecosystem ensures that materials, systems, and processes meet regulatory requirements while remaining safe, high-performing, and sustainable throughout their lifecycle.

Conformity assessment organisations, including the ICC Evaluation Service (ICC-ES), play a key role by providing independent verification of product performance, structural integrity, fire ratings, and sustainability claims. ICC-ES enhances transparency and verifiability through Evaluation Reports (ESR), Environmental Product Declarations (EPD), and Verification of Attributes Reports (VAR).

An opportunity for the GCC to demonstrate regional leadership

The GCC is uniquely positioned to lead in transparent sustainability. Rapid urbanisation, iconic megaprojects, and growing international influence mean that today’s construction decisions will shape the region’s environmental legacy for generations.

The UAE has established energy efficiency standards for buildings, while Saudi Arabia invests in net-zero cities such as NEOM. Oman, collaborating with ICC, is developing national building codes aligned with global best practices and adapted to local requirements.

The I-Codes remain central, providing rigorous frameworks for material performance, energy conservation, water efficiency, and more. This integrated approach fosters a cohesive system that encourages the highest standards of safety, quality, and innovation across the construction industry.

As Mohamed Amer said, “The buildings we construct today will stand for decades. It is important that transparent sustainability is embedded in the entire regulatory ecosystem that governs construction.” Achieving this requires up-to-date building codes, certified product evaluations, inspections, training, and continuous professional development to ensure lasting impact.

At The Mining Show 2025 held in Dubai from November 17-18, global leaders and industry innovators converged to chart the future of mining at a time of unprecedented energy transition and technological upheaval.

In a keynote that set the tone for the event, H.E. Saif Ghubash Almarri, representing the UAE, painted a compelling picture of a world in flux and positioned the nation at the forefront of strategic change.

Almarri articulated the sweeping transformations at play, noting, “Today, the world is undergoing a profound transformation. This has become the backbone of both energy transition and digital transit—without electricity, there is no mobility, no AI, and no resilient digital economy.” Drawing on International Energy Agency data, he projected that demand for key minerals will “increase up to 500% by 2050,” signifying not mere “small adjustments” but seismic shifts in supply chains and geopolitical relations.

To meet these challenges, Almarri highlighted the UAE’s robust, multi-pronged approach. Major initiatives such as the National 3D Geological Model and the Energy and Infrastructure National Digital Platform have been launched to strengthen supply chain resilience, expedite exploration, and boost efficiency.

He emphasised that the UAE is not just adapting, but actively shaping the industry’s evolution, citing expanded investments in aluminum, copper, nickel, and lithium, and a firm commitment to low-carbon extraction and digital traceability. “The future will belong to those who prepare with clarity, ambition and action. The UAE’s message is clear: we are prepared. We are confident,” Almarri asserted.

Safety, innovation, and environmental stewardship were then championed by Abdul Rahman Al Mansoori, who underscored the dual challenges of rapid growth and unique regional conditions. He pointed to initiatives seeking to “reduce the amount of glass, one explosive and above the road,” making transport safer and harmonising skills and standards across the sector. Al Mansoori noted, “We see great opportunity in AI and automation. These tools can help prevent accidents and grow safety and increase productivity.”

From Saudi Arabia, Hassan M.H. Almarzouki detailed extraordinary growth in the Kingdom’s mining sector, with exploration spending soaring from $5 million in 2020 to US$280mn in 2024. He credited a strategic overhaul and new mining laws for this acceleration, and called on the global industry: “We are building a world class, sustainable mining industry that is open for business and drives partnership opportunity.”

As international stakeholders look toward a future defined by resilience, digitisation, and sustainability, The Mining Show 2025 illuminated both the scale of change and the spirit of collaboration needed to harness it.

Emirates Global Aluminium (EGA), TAQA, DUBAL Holding, and the Emirates Water and Electricity Company (EWEC) have signed a series of landmark agreements aimed at decarbonising aluminium production and expanding renewable and clean energy development in Abu Dhabi.

The agreements mark a significant step in Abu Dhabi’s strategy to strengthen industrial sustainability while advancing low-carbon energy infrastructure. They support EGA’s ambition to become a global leader in net-zero aluminium by 2050, bolster EWEC’s solar power initiatives, and enhance the efficiency of power generation across the Emirate.

The signing ceremony was attended by top executives, including Farid Al Awlaqi, CEO of TAQA Generation; Abdulnasser Bin Kalban, CEO of EGA; Ahmad Hamad Bin Fahad, CEO of DUBAL Holding; and Ahmed Ali Alshamsi, CEO of EWEC, alongside His Excellency Dr Abdulla Humaid Al Jarwan, Chairman of the Abu Dhabi Department of Energy.

Under the agreements, TAQA and DUBAL Holding will acquire EGA’s power and water generation assets in Al Taweelah for USD $1.9bn (ca. AED 7 billion). The plant, Abu Dhabi’s third-largest, has a capacity of 3.1GW and can desalinate 6.25 million imperial gallons of water per day, using high-efficiency combined-cycle gas turbines and reverse osmosis technology. Operations will be managed through a joint venture company equally owned by TAQA and DUBAL Holding.

Further agreements signed

EWEC will purchase power from the plant under a long-term Power Purchase Agreement until 2049, providing a flexible electricity supply to support the integration of renewable and clean energy. TAQA Transmission will also acquire EGA’s electricity transmission assets, with capacity from the grid to EGA sites set to rise from 640 to 3,360MVA by 2027.

EGA has signed Abu Dhabi’s largest-ever electricity supply agreements, securing 23TWh annually for 24 years, with an increasing share from renewable and clean sources. The move will accelerate production of CelestiAL solar aluminium and MinimAL low-carbon aluminium, potentially making up almost half of EGA’s total primary aluminium output by 2028. Production of these low-carbon grades will rise from Q4 2025, with opportunities to procure additional clean energy certificates.

His Excellency Dr Abdulla Humaid Al Jarwan described the initiative as a demonstration of Abu Dhabi’s “future-focused approach” and collaborative ecosystem. Abdulnasser Bin Kalban said the project “makes EGA a leader in our industry’s drive towards a more sustainable future,” while Jasim Husain Thabet of TAQA highlighted the agreements’ role in “significantly reducing emissions and advancing a cleaner energy future.”

EWEC projects the initiative will cut 3.5 million tonnes of greenhouse gas emissions annually by 2035, over three per cent of Abu Dhabi’s current emissions, marking a new benchmark for sustainable industrial growth in the UAE.

The EU’s Vision Zero initiative, aiming for zero fatalities and serious injuries on European roads by 2050, has brought road safety into sharp focus.

While infrastructure improvements and driver training remain important, the spotlight has shifted to standardising vehicle safety technology. This is the aim of the EU General Safety Regulation (GSR), a comprehensive framework mandating advanced safety features in new vehicles.

For Europe’s largest asset-based logistics company, Girteka, the results are already evident. The GSR was introduced to tackle the human error factor, which accounts for up to 90% of road accidents, and to make vehicles safer for both occupants and Vulnerable Road Users (VRUs) such as pedestrians and cyclists. Its phased implementation began in July 2022 for new vehicle types with basic advanced systems, progressing to all new registrations in July 2024, requiring a full suite of eight mandatory Advanced Driver Assistance Systems (ADAS) on trucks and buses, including blind spot detection, advanced emergency braking (AEB), lane-keeping assistance, intelligent speed assistance, and driver fatigue monitoring.

Eurostat reports that in 2024 there were over 4 million goods vehicles registered in the EU, with vehicles over 30 tonnes completing 83.1% of total freight transport in tonne-kilometres. HGVs under two years old accounted for 20.2% of road freight, highlighting the sector’s rapid fleet renewal. Manufacturers including Volvo, Scania, Mercedes-Benz, DAF, and MAN have embraced the regulations, incorporating ADAS technologies that were previously optional.

Real-world impact

Scania noted that its trucks already had “most of the required safety assistance technology,” while DAF and Volvo confirmed compliance and projected further advancements in active safety technology. Anna Wrige Berling, Traffic and Product Safety Director at Volvo Trucks, said, “Looking further ahead, trucks will become more intelligent and more active when it comes to safety, with more features that intervene rather than just inform,” emphasising that drivers remain “the most important safety system in the truck.”

Girteka’s experience demonstrates the real-world impact of these regulations. Since July 2024, the company has added over 2,400 GSR-compliant trucks to its fleet, with plans for up to 8,000 more by 2026. Internal data shows a 10% reduction in accidents within a year, particularly in low-speed manoeuvres, small collisions, and blind spot incidents, the very scenarios the new ADAS technologies were designed to address.

Dainius Augutis, Transport Function & Support Department Manager at Girteka, said, “The EU's GSR is a powerful market signal that pushes safety technology from a premium add-on to a universal standard. The collaboration between fleet owners like Girteka, who provide the data and demand, and manufacturers, who provide the engineering, is what makes Vision Zero achievable.”

Beyond metrics, the human impact is profound. Drivers benefit from safer conditions and lower stress, communities face reduced risks, and clients experience fewer disruptions. By combining regulation, advanced technology, and comprehensive driver training, Girteka shows that safety excellence is inseparable from operational excellence. The company’s results underline that well-designed regulations and proactive fleet investment can accelerate safety innovation, offering a blueprint for the future of safer, smarter logistics across Europe.

IEA reports 76 million employed in energy sector in 2024, but skilled labour shortages pose challenges

Significant global investment in energy infrastructure drove a 2.2% rise in energy-sector employment last year, nearly double the rate of job growth in the broader world economy, according to a new IEA report

The World Energy Employment 2025 report, released today, shows that the global energy workforce reached 76 million in 2024, an increase of over five million roles since 2019. Over the last five years, the energy sector has contributed 2.4% of all net new jobs created worldwide.

The power sector has been a key driver of this growth, accounting for three quarters of recent employment gains and now ranking as the largest employer in energy, overtaking fuel supply. Solar PV remains a major driver, complemented by expanding employment in nuclear power, electricity grids, and energy storage. As electrification spreads across industries, roles in EV manufacturing and battery production surged by nearly 800,000 in 2024.

Fossil fuel employment remained resilient throughout the year. Coal-sector jobs rose in India, China, and Indonesia, lifting coal employment 8% above 2019 levels despite sharp declines in advanced economies. The oil and gas industry has regained most of the jobs lost in 2020, although low prices and economic uncertainty have triggered some workforce reductions in 2025. Early data suggest that overall energy-sector employment growth may moderate to 1.3% this year, as tight labour markets and geopolitical tensions prompt caution among employers.

Despite the sector’s strong growth, the report highlights a worsening shortage of skilled workers. More than half of the 700 companies, unions, and training institutions surveyed through the IEA’s Energy Employment Survey reported critical recruitment bottlenecks that could delay infrastructure projects, slow major initiatives, and increase system costs.

“Energy has been one of the strongest and most consistent engines of job creation in the global economy during a period marked by significant uncertainties,” said IEA executive director Fatih Birol. “But this momentum cannot be taken for granted. The world’s ability to build the energy infrastructure it needs depends on having enough skilled workers in place. Governments, industry and training institutions must come together to close the labour and skills gap. Left unaddressed, these shortages could slow progress, raise costs and weaken energy security.”

Technical and applied roles such as electricians, pipefitters, line workers, plant operators, and nuclear engineers are particularly hard to fill. These occupations have added 2.5 million jobs since 2019 and now represent more than half of the global energy workforce, more than double their share of total employment across the wider economy.

Demographic pressures are also intensifying. In advanced economies, 2.4 energy-sector workers are nearing retirement for every new entrant under 25. Nuclear and grid-related professions face some of the steepest ageing challenges, with retirement-to-new-entrant ratios of 1.7 and 1.4 to 1, respectively.

At the same time, the supply of newly trained workers is insufficient to meet demand. To prevent the skills gap from widening by 2030, the number of new qualified energy workers globally must increase by 40%. Achieving this would require an additional US$2.6bn per year, less than 0.1% of total global education spending.

The report stresses that policy action can help address these challenges. Respondents identified training costs, foregone wages, and limited awareness of programmes as major barriers to entry. Effective measures include financial incentives for learners, expanded apprenticeship schemes, increased private-sector participation in curriculum design, and investment in training facilities. Reskilling within the sector is also essential. While some regions are already seeing declines in fossil fuel employment, targeted retraining programmes could help workers transition to fast-growing areas of the energy system.

Ariston Middle East is preparing to showcase its newest line-up of innovative, future-ready and sustainable water-heating solutions at Big 5 Global 2025, taking place from 24-28 November at the Dubai World Trade Centre.

The company’s latest technologies will be featured in Hall 3, Stand 3A131, within the pavilion of regional distributor MAHY Khoory, reinforcing Ariston’s long-standing brand promise: “The Home of Sustainable Comfort.”

“The Big 5 Global stands as the construction industry's most important and influential gathering, firmly rooted in Dubai,” said Alberto Torner, Head of International Markets (AMEA) at Ariston Group. “Thermal comfort has historically placed a significant burden on electrical networks and contributed to CO₂ emissions. As a global specialist with a 95-year heritage and leadership in over 40 countries, it is our responsibility to guide the conversation around energy transition. At Big 5, we are proud to showcase three innovative solutions that highlight the sustainability-driven technology embedded across our range.”

Taking centre stage at the exhibition is one of Ariston’s advanced heat-pump water-heating systems, the Nuos FIT. This compact thermodynamic water heater extracts heat from the surrounding air to dramatically reduce electricity consumption, delivering up to 50 per cent energy savings compared to traditional electric models. Using the environmentally friendly R290 refrigerant, it performs effectively across a wide temperature range from +7 °C to +42 °C and can achieve storage temperatures of 62 °C without relying on a backup heater. Four operating modes — Green, Green Plus, Boost and i-Memory — along with smart remote control via the Ariston NET app, further enhance efficiency and convenience.

Ariston will also feature the Velis Tech WiFi, an electrical water heater engineered to reduce energy use without compromising performance. With an ultra-slim 27 centimetre depth and twin-tank configuration, it offers faster heating and increased hot-water availability. Its ECO EVO mode intelligently learns household patterns to deliver up to 25 per cent energy savings, while the Boost function heats both tanks rapidly to 80 °C. Wi-Fi connectivity allows users to manage scheduling, monitor consumption and adjust settings through the Ariston NET app.

Completing the line-up is the PRO1 Eco, introduced earlier this year in the UAE. Powered by the patented CoreTECH-enabled ECO EVO system, it analyses daily usage habits to heat water only when needed. This results in up to 14 per cent reduced energy consumption while ensuring continuous comfort, making it well suited to sustainability-focused homes.

“We remain committed to leading the market through continuous innovation and product excellence,” Alberto Torner, Head of International Markets (AMEA) at Ariston Group concluded. “With 45 years of strong presence in the GCC, our comprehensive portfolio is perfectly aligned with the region’s sustainability goals. We invite all attendees of Big 5 Global 2025 to visit us in Hall 3 and experience our next-generation water-heating technologies firsthand.”

The Wirtgen Group has announced the appointment of Panafrican Equipment Group as its new authorised dealer, expanding access to its complete line of products and technologies across Kenya, Tanzania, Uganda, Rwanda and Burundi in East Africa, as well as Ghana and Sierra Leone in West Africa

In Nigeria, the partnership will specifically cover the group’s minerals and soil compaction portfolio.

A long-standing partner across Africa

For decades, the Wirtgen Group has maintained a strong presence on the continent. Its six specialist brands – Wirtgen, Vögele, Hamm, Kleemann, Benninghoven and Ciber – work in synergy to meet the specific requirements of customers across diverse sectors. Together, they bring proven expertise and extensive industry knowledge to African markets. “With the innovative road construction and mineral solutions, the Wirtgen Group is well equipped to meet future challenges”, says Jerry Muchiri, Manager Regional Business and Dealer Development East Africa and Nigeria at Wirtgen International GmbH.

Panafrican’s strong after-sales commitment

Panafrican’s established footprint and its commitment to high-quality service delivery will further strengthen access to Wirtgen Group’s technologies throughout the region. “As authorised dealer, Panafrican provides complete support for all construction and mineral processing needs, combining our service expertise with Wirtgen Group's innovative portfolio and applications know how,” commented Scott McCaw, CEO and managing director Panafrican Group.

The collaboration positions both companies to deliver enhanced customer support and reinforces their shared dedication to innovation, quality and customer-centric service.

Strong partnerships between mines and their supply partners are built on optimising the health of productive assets, which remain at the core of operational efficiency. Collaboration and partnership need to add value on both sides; where insufficient value is created, there can be little room for meaningful collaboration.

FLS’s strategy begins with a strong global footprint, ensuring proximity to its customer base. This allows for not only quick response times but also proactive maintenance strategies. Regular visits and continuous engagement support asset health beyond the traditional reactive approach.

A proactive stance brings benefits such as ongoing performance monitoring, training, and skills transfer – all of which contribute to long-term productivity and improved asset performance.

Beyond the capital acquisition stage, productive partnerships also enhance adaptability of the operation to the changing characteristics of ore bodies over time. These changes affect key feed parameters and influence the consumption of water, power, and reagents.

Partnerships are also rooted in a shared commitment to sustainability and in reducing the environmental impact of mining and processing activity. This includes minimising carbon emissions through energy efficiency. This means making the most of equipment capacity through technology that enhances efficient operation while increasing throughput. Leveraging advanced technology, such as LoadIQ mill scanner technology, enables operations to optimise mill capacity – delivering greater throughput from the same asset and power draw.

Research and development are critical drivers of these sustainability efforts. Innovations such as FLS’s NexGen polyurethane screen panels are extending wear life by up to four times, supporting more efficient operations with longer periods between replacement and maintenance. This improves plant uptime, boosts efficiency, and ensures capital investment delivers the best value while minimising operating costs.

Recycling of wear parts is another important element of responsible asset management. While technologies like composite liners extend lifespan, eventual replacement is inevitable. FLS’s circular economy approach includes solutions for recycling worn liners, reducing waste in the value chain and supporting customers in meeting their sustainability requirements.

Digital advancements also play a vital role. FLS’s PerformanceIQ® provides a holistic platform that integrates asset health and performance monitoring. By linking condition monitoring and asset health, the platform ensures optimal performance. Continuous monitoring helps shift asset management from a reactive to a proactive approach, reducing downtime and enhancing overall productivity. AI and digital solutions empower operators with better insights, enabling data-driven decision making and proactive maintenance strategies.

Through these combined initiatives, FLS reinforces its role as a trusted partner, supporting mines in achieving sustainable productivity while optimising the health and performance of their assets.

The new drive system delivers 20% higher torque than the original design, significantly enhancing the mill’s aluminum processing capabilities. (Image source: SMS Group)

SMS group has successfully completed a major modernisation project at Gulf Aluminium Rolling Mill B.S.C. (GARMCO), a leading aluminum producer based in Manama, Kingdom of Bahrain, upgrading the motors and drives in the one-stand reversing hot rolling mill

Originally built by a third-party supplier, the mill has now been restored to full operational capacity and equipped to meet future demands in aluminum processing.

The upgrade replaced outdated DC motors with three-phase AC motors and advanced drive technology, including variable frequency drive systems powered by active front ends and new transformers. The new drive system delivers 20% higher torque than the original design, significantly enhancing the mill’s aluminum processing capabilities.

“The completion of this modernisation project is a testament to our commitment to maintaining world-class operational standards. SMS group’s expertise and advanced technological solutions have provided us with greater reliability and efficiency in our hot mill operations,” said Ebrahim Khalil, executive manager Operations at GARMCO.

The project scope was comprehensive, covering plant engineering, electrics and automation, equipment procurement and manufacturing, as well as installation and commissioning supervision. At the heart of the modernisation was SMS’s innovative twin-motor drive train equipment, featuring a custom gearbox to combine two electric motors with a rated power of 2150 KWs each, paired with two SMS giant torque spindles. The design offers high power capability, reduces space requirements, lowers investment costs, and provides some operational redundancy.

Additional equipment included the X-Pact Drive low-voltage frequency converter for the entry and exit coilers, a medium-voltage converter operated in load share mode, and transformers to supply the new systems. The equipment was tailored to GARMCO’s demanding operations, which include producing aluminum coils, tread plates, slit coils, and foils for industrial applications such as packaging and heat exchange systems.

The modernisation strengthens the collaboration between GARMCO and SMS group. This is the first joint project of this scale, reflecting SMS’s reputation for high-performance, reliable solutions with optimised technical features and superior power efficiency. The new drive system provides enhanced torque across the full speed range, a critical factor for rolling operations requiring high torque at elevated speeds.

“The project highlights the strong partnership between both companies and demonstrates how innovative solutions can elevate operational efficiency,” the SMS team noted.

Having previously supported GARMCO with technical services for its scalper machine, SMS group has built a foundation of trust and collaboration. With the hot rolling mill now modernized, GARMCO is well-positioned to deliver sustained operational excellence and produce high-quality aluminum products for its global customers.

Italian shipbuilder Fincantieri and ASRY (Arab Shipbuilding & Repair Yard) have signed an Memorandum of Understanding (MoU) to explore new opportunities for collaboration in the shipbuilding sector

Under the MoU, the two sides will jointly evaluate opportunities for the design and construction of offshore service and military vessels up to 80 metres in length, as well as the potential for export contracts in the Gulf area.

The agreement also includes maintenance, repair, and overhaul (MRO) services for military, commercial and offshore vessels, as well as the exchange of know-how in naval design and production process optimisation.

The military vessels would be intended for use by the Bahrain Navy and Coast Guard.

ASRY is a leading operator in ship repair and marine services in the Gulf of Bahrain.

Fincantieri was represented by its chairman, Biagio Mazzotta, and Eugenio Santagata, general manager of the Fincantieri Naval Vessels Division, who signed the agreement together with Ahmed AlAbri, CEO of ASRY.

Pierroberto Folgiero, CEO and managing director of Fincantieri, said the MoU represents an opportunity for Fincantieri to enter the Bahraini shipbuilding market and is a further step in consolidating the group's strategy and presence in the Middle East.

“This agreement strengthens our strategic position in the Gulf and confirms Fincantieri's desire to develop long-term industrial partnerships with leading partners such as ASRY,” said Folgiero.

“By combining complementary skills and converging visions, we are laying the foundations for a solid and structured presence in the Bahraini shipbuilding market, in line with the objectives of our integrated export platform in the Middle East.”

The signing of the MoU took place on the sidelines of the 46th Gulf Cooperation Council Summit in the presence of Italian President of the Council of Ministers Giorgia Meloni, and Bahrain’s Crown Prince and Prime Minister His Royal Highness Salman bin Hamad Al-Khalifa.

Separately, Fincantieri announced a partnership In Saudi Arabia with King Abdullah University of Science and Technology (KAUST) to establish a scholarship aimed at supporting young researchers in maritime security, cyber-resilience and emerging applied navigation technologies.

It follows an MoU signed last January and reflects a shared commitment of both sides in promoting excellence in education and technology transfer, in line with Saudi Arabia’s Vision 2030, a Fincantieri statement read.

“The scholarship will enable young and talented researchers to develop innovative solutions to counter new threats to navigation, such as recent cases of AIS and GPS spoofing, which can alter vessel positions and compromise the safety of shipping routes,” it stated.

The programme will focus on three strategic areas: the advanced authentication of AIS signals to prevent manipulation; the opportunistic detection of GPS spoofing through intelligent satellite data analysis, and star-based position verification enhanced by machine learning algorithms.

Fincantieri added that the goal is to develop an operational software platform that can be integrated into on-board digital systems, strengthening the collaboration between universities and industry and contributing to the growth of the Fincantieri Digital Ecosystem (FDE).

Most Read

-

-

-

-

-

-

-

-

- Details

-

-

-

-

-

Latest News

Most Read

Latest News

More Articles

The integrated digital platform is designed to enhance the speed and effectiveness of national response efforts.